Voltage Calibrator Market

Voltage Calibrator Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Component (Product, Services), By Device Type (Bench Type, Handheld), By Application (Testing and Troubleshooting, Process Device Calibration, Research and Development, Others), By Industry (Aerospace and Defense, Semiconductor, Healthcare, IT and Telecommunication, Others), By Region & Competition, 2019-2029

Published Date: June - 2025 | Publisher: MIR | No of Pages: 320 | Industry: Power | Format: Report available in PDF / Excel Format

View Details Buy Now 2890 Download Free Sample Ask for Discount Request Customization| Forecast Period | 2025-2029 |

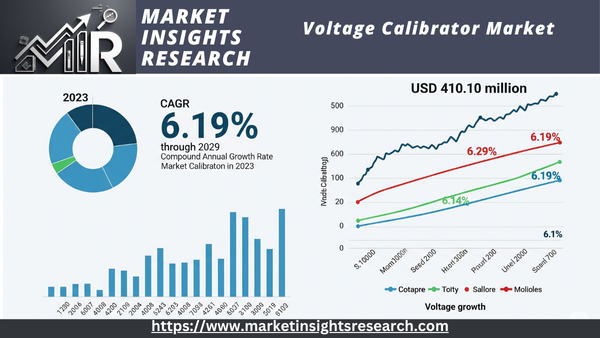

| Market Size (2023) | USD 410.10 Million |

| Market Size (2029) | USD 593.31 Million |

| CAGR (2024-2029) | 6.19% |

| Fastest Growing Segment | IT and Telecommunication |

| Largest Market | North America |

Market Overview

Global Voltage Calibrator Market was valued at USD 410.10 million in 2023 and is anticipated to project robust growth in the forecast period with a CAGR of 6.19% through 2029. The Voltage Calibrator market refers to the industry involved in the design, production, and distribution of devices essential for ensuring the accuracy and reliability of voltage measurements.

Download Free Sample Ask for Discount Request Customization

Precision tools called voltage calibrators are used in various industries, such as electronics manufacturing, energy, aerospace, and healthcare, to check and modify the voltage output of sensors and measurement devices. By offering a uniform reference for voltage measurements, these instruments are essential to preserving the accuracy of electronic devices, control systems, and testing apparatus. The market is defined by a persistent focus on technical innovation, meeting changing industry demands, and adhering to strict legal and quality standards. The market for voltage calibrators is a crucial part of the larger instrumentation and calibration sector, which supports optimal performance, standard compliance, and dependability in various applications as companies place a greater emphasis on accurate measurements.

Key Market Drivers

Technological Advancements and Innovation in Voltage Calibration

The global voltage calibrator market is significantly shaped by technical breakthroughs in the quickly changing field of electrical devices and instrumentation. Manufacturers are forced to innovate and create state-of-the-art calibration solutions as industries continue to demand greater precision and accuracy in their measuring processes.

The incorporation of cutting-edge technologies like digital signal processing (DSP) and microprocessor-based control systems in voltage calibrators is one of the main factors propelling the market. By producing more dependable and effective outcomes, these technologies improve the calibration process and eventually aid in the market's expansion. Additionally, in response to the growing need for simplified and intuitive calibration solutions, the integration of intelligent features such as automated calibration processes and remote control capabilities has emerged as a noteworthy trend.

The ongoing pursuit of increased precision and dependability also motivates firms to spend money on R&D, which promotes an innovative culture in the sector. The worldwide voltage calibrator market will continue to rise because of this dedication to technological excellence, which satisfies end customers' present needs and foresees their future ones.

Stringent Quality Standards and Regulatory Compliance

The need for accurate and traceable measurements has increased as companies become more regulated and quality-conscious. This is especially true in industries where following international standards is crucial, such manufacturing, healthcare, and aerospace. The demand for calibration solutions that adhere to strict quality standards and regulations is driving the global voltage calibrator market.

Manufacturers in this sector are forced to create calibrators that either meet or beyond industry-specific requirements, including those established by the National Institute of Standards and Technology (NIST) or the International Organization for Standardization (ISO). End users are reassured that their measurement tools are accurate and dependable by the assurance of compliance.

The need for advanced voltage calibrators is further fueled by the growing emphasis on traceability, or the capacity to link data to predetermined standards. In addition to meeting their clients' urgent needs, manufacturers who adhere to strict quality standards and regulatory requirements establish themselves as reliable partners in sectors where accuracy is crucial.

Download Free Sample Ask for Discount Request Customization

Growth in Industrial Automation and Electronics Manufacturing

The global voltage calibrator market has grown dramatically as a result of the rise in industrial automation and the pervasive use of electronics in production processes. The need for accurate and reliable voltage references for control systems, sensors, and instrumentation has grown as automation spreads throughout sectors.

Voltage calibrators are essential for preserving the precision of electronic parts, which guarantees the smooth operation of automated systems. Reliable calibration instruments are essential for maintaining product quality in electronics manufacturing, where complex and delicate components are frequently produced. It is anticipated that this demand would rise in lockstep with the global expansion of the electronics manufacturing and industrial automation industries.

By decreasing errors and downtime, the incorporation of voltage calibrators into automated production lines improves efficiency. Manufacturers in these industries understand how crucial it is to spend money on top-notch calibration solutions in order to streamline their operations and guarantee the reliable operation of electrical gadgets.

Increasing Emphasis on Preventive Maintenance and Calibration Services

Preventive maintenance has become more important across industries as a result of the paradigm change from reactive to proactive maintenance practices. This change is a major factor propelling the worldwide market for voltage calibrators as businesses look to prolong the life of their equipment and prevent expensive downtime.

Preventive maintenance procedures require calibration services, which include routine inspections and adjustments utilizing sophisticated voltage calibrators. Businesses understand that preventing equipment failures is more cost-effective than fixing problems after they arise. The market for premium voltage calibrators is being driven by this mentality, which has resulted in an increase in the need for thorough calibration services.

In response to this need, calibration industry manufacturers and service providers are providing calibration solutions with features including automated calibration procedures, predictive maintenance analytics, and remote monitoring. These characteristics fuel the use of sophisticated voltage calibrators, aligning with the evolving needs of companies implementing preventive maintenance.

Globalization and Cross-Border Trade of Electronic Equipment

The global market for voltage calibrators has grown dramatically as a result of the globalization of industries and the rise in cross-border trade in electronic equipment. Standardized calibration procedures are necessary to guarantee consistency and accuracy in measurements as electronic devices and components are traded and used globally.

Voltage calibrators offer a consistent reference for voltage measurements, which makes it easier to integrate electrical devices. Following international calibration standards becomes essential in a globalized market because goods may be produced in one nation and used in another. Because of this, there is now a greater need than ever for top-notch voltage calibrators that can produce precise and traceable readings regardless of location.

Calibration solutions that can adjust to a variety of surroundings and operating situations are necessary due to the growing complexity of global supply chains. In order to meet this demand, the global voltage calibrator market provides robust and adaptable calibration solutions, bolstering the interconnectedness of the modern electronic sector.

Rising Awareness of Calibration Importance Across Industries

The growing industry awareness of the crucial role calibration plays in guaranteeing the precision and dependability of measuring devices is one of the main factors propelling the worldwide voltage calibrator market. It is becoming increasingly clear that accurate measurements are essential to quality control, safety, and compliance as industries and technology develop.

To ensure the accuracy of their measurement tools, sectors like telecommunications, energy, and pharmaceuticals are investing more on calibration solutions. Large corporations are not the only ones with this increased awareness; small and medium-sized businesses (SMEs) looking to improve their quality assurance procedures are also affected.

Industry practices now include education and training programs on the value of calibration and the function of improved voltage calibrators. Businesses are realizing that investing in top-notch calibration equipment up front yields long-term advantages like higher-quality products, adherence to industry standards, and increased operational effectiveness.

Technological developments, regulatory pressures, industrial automation trends, preventive maintenance plans, cross-border trade dynamics, and a growing understanding of the value of calibration across a range of industries all interact to drive the global voltage calibrator market. Together, these factors influence the market, encouraging creativity and the creation of cutting-edge calibration solutions that satisfy the changing demands of a quickly growing technological environment.

Government Policies are Likely to Propel the Market

Standardization and Regulatory Compliance in Voltage Calibration

Governments may enact laws designed to offer incentives for research and development (R&D) activities in order to promote creativity and technological breakthroughs in the calibration sector. These incentives, which aim to encourage investment in state-of-the-art calibrating technologies, could be in the form of tax credits, grants, or subsidies.

Research and Development Incentives for Calibration Technologies

Governments may enact laws designed to offer incentives for research and development (R&D) activities in order to promote creativity and technological breakthroughs in the calibration sector. These incentives, which aim to encourage investment in state-of-the-art calibrating technologies, could be in the form of tax credits, grants, or subsidies.

Environmental Regulations and Sustainable Practices

Governments are increasingly incorporating environmental rules into laws governing the manufacture and use of electronic equipment, including voltage calibrators, in response to the global movement for environmental sustainability. From the manufacturing stage until the disposal of calibrating technologies at the end of their useful lives, these laws seek to reduce their negative effects on the environment.

Regulations may mandate that producers use recyclable materials, cut energy use, and implement environmentally friendly production techniques while building voltage calibrators. Governments may also impose strict regulations on how electronic waste should be disposed of, which would encourage manufacturers to create products that are recyclable and environmentally friendly.

The market for voltage calibrators can support sustainable practices and show corporate responsibility by adhering to certain environmental regulations. In addition to meeting legal requirements, manufacturers who put an emphasis on eco-friendly design and production methods also attract eco-aware customers and businesses, which promotes long-term market viability.

Essentially, environmental regulations and government policies offer a framework for the worldwide voltage calibrator market to adopt sustainable practices, guaranteeing a balance between environmental stewardship and technical growth.

Trade and Tariff Policies Affecting Voltage Calibration Equipment

The global market for voltage calibrators is significantly impacted by trade and tariff laws, which also affect the dynamics of calibration equipment import and export. Governments have a significant influence on these regulations, which can either help or hinder the movement of voltage calibrators across international borders.

In order to foster global cooperation and the sharing of technological know-how, countries occasionally enact laws that support the free trade of calibrating equipment by lowering tariffs and trade restrictions. This creates a competitive market environment where consumers have more options and producers can reach international markets.

On the other hand, by restricting access to particular areas or raising the price of imported calibration equipment, protectionist policies that place tariffs or trade restrictions on voltage calibrators can impede market expansion. Concerns about resolving trade imbalances or safeguarding home industries may be the driving forces behind these measures.

In the market for voltage calibrators, manufacturers and consumers depend heavily on the stability and predictability of trade and tariff regulations. A favorable climate for market expansion is created by governments that enact clear and uniform trade laws, which promote healthy competition and international technical interchange.

Cybersecurity Regulations for Calibration Equipment

Governments are realizing more and more how crucial cybersecurity is to protecting vital infrastructure, such as measurement and calibration systems, as digitalization continues to spread throughout businesses. Regulations pertaining to cybersecurity for calibration equipment are designed to fix weaknesses and guard against any online attacks that can jeopardize the precision and dependability of voltage calibrators.

Manufacturers may be required to follow cybersecurity guidelines while designing and producing calibrating equipment as a result of these policies. In order to handle new cybersecurity threats and vulnerabilities, governments may also demand frequent updates and patches.

Governments can enhance the overall resilience of the voltage calibrator sector by enacting strict cybersecurity rules. End users can feel secure knowing that their calibration equipment is immune to cyber threats that could jeopardize the accuracy of measurements and data, especially in industries where accurate measurements are vital.

In an increasingly linked and digitalized world, government regulations pertaining to cybersecurity for calibration equipment are essential to guaranteeing the security and dependability of voltage calibrators.

Training and Certification Standards for Calibration Professionals

The integrity of calibration procedures depends on a workforce that is properly trained, and governments can affect this by enacting laws pertaining to calibration professional certification and training requirements. The purpose of these regulations is to guarantee that those engaged in calibration operations have the abilities and know-how required to carry out precise and trustworthy measurements.

To create certification programs and training requirements for calibration specialists, governments can work with academic institutions and trade associations. These courses might address a variety of subjects, including as instrumentation, metrology, and voltage calibrator operation. For specialists to operate on particular types of equipment or practice calibration in particular industries, certification may be necessary.

Governments support the general competency and professionalism of the workers in the calibration industry by placing a strong emphasis on training and certification. Consequently, this improves measurement accuracy and the legitimacy of calibration procedures, which benefits the worldwide voltage calibrator market.

From standardization and regulatory compliance to incentives for R&D, environmental sustainability, trade dynamics, cybersecurity, and workforce training, government policies have a significant impact on the global voltage calibrator market. Together, these regulations provide a framework that shapes the market for voltage calibrators and makes sure it adapts to changing societal, technological, and environmental demands.

Key Market Challenges

Evolving Technological Complexity and Integration

The growing complexity of technology and the ensuing integration needs are the main issues confronting the global voltage calibrator market. The need for voltage calibrators that can handle a broad range of complex systems has increased as electronic devices become more varied and sophisticated. For manufacturers, this poses a significant obstacle as they work to stay up with the rapidly changing technical environment.

Maintaining compatibility is a difficulty for voltage calibrators due to the fast integration of digital signal processing (DSP), Internet of Things (IoT) capabilities, and sophisticated microprocessor-based control systems in electronic equipment. The complex calibration requirements of these cutting-edge technologies, which frequently entail complex communication protocols and multiple calibration requirements, necessitate calibration solutions to adapt.

The difficulty of integration goes beyond technical intricacy to include the wide variety of industries that use voltage calibrators. Every industry has different calibration needs that are driven by particular applications and legal restrictions, ranging from aerospace to healthcare. For manufacturers, modifying voltage calibrators to accommodate this variability while preserving accuracy and precision adds another level of complexity.

In order to maintain the versatility and adaptability of their voltage calibrators, manufacturers must negotiate the complex terrain of industry-specific integration needs and technical improvements. Companies in the worldwide voltage calibrator market must cultivate an innovative and agile culture since this task requires constant investments in research and development to stay ahead of the curve.

Manufacturers, industry stakeholders, and regulatory agencies must work together to address the problem of growing technical complexity. A framework for creating calibration solutions that complement the varied and quickly evolving technical landscape can be established through standardization initiatives and the creation of industry-specific guidelines. By overcoming this obstacle, the worldwide market for voltage calibrators can keep producing dependable calibration instruments that satisfy the demands of an ever-more intricate electronic ecology.

Regulatory Compliance and Harmonization Across Borders

Navigating the complicated terrain of regulatory compliance and attaining cross-border harmonization are major challenges for the worldwide voltage calibrator industry. Because voltage calibrators are essential to sectors where accurate measurements are crucial, strict adherence to quality standards and laws is needed. However, due to regional variations in standards and criteria, producers face significant challenges in attaining global regulatory compliance.

Regulations and standards governing measurement tools vary by nation and region and are frequently created by regional authorities, the National Institute of Standards and Technology (NIST), or the International Organization for Standardization (ISO). Because of this, the regulatory environment is fragmented, and in order to reach different markets, voltage calibrator producers must guarantee adherence to numerous standards.

The dynamic nature of regulatory environments, where standards are regularly updated or amended to reflect industry best practices and technological improvements, makes the task even more difficult. In order to remain in compliance, manufacturers must constantly adapt their goods, stay up to date on these modifications, and go through recertification procedures.

Cross-border regulatory harmonization is a difficult undertaking that calls for international cooperation and standardization initiatives. The worldwide reach of voltage calibrator producers may be restricted by trade barriers resulting from disparities in regulatory requirements. Furthermore, the absence of harmonization could raise the price of compliance testing and certification, which would reduce market competitiveness.

Governments, standardization organizations, and industry stakeholders must work together to create uniform frameworks and standards for voltage calibrators in order to overcome this difficulty. This includes initiatives to promote a globally accepted set of calibration standards, expedite certification procedures, and harmonize regional laws.

The difficulty of cross-border harmonization and regulatory compliance emphasizes the necessity of a concerted and cooperative strategy in the global voltage calibrator business. Manufacturers may better navigate the regulatory environment and make sure their products satisfy the various compliance requirements of the global market by finding common ground on standards and working toward harmonization.

Key Market Trends

Increasing Adoption of Automated Calibration Solutions

Automated calibration solutions are becoming increasingly popular in the global voltage calibrator industry. Because automated calibration systems reduce human error and streamline the calibration process, they are growing in popularity as companies aim for increased productivity, accuracy, and efficiency.

The increasing complexity of contemporary electronic gadgets and systems is a major factor driving this trend. The necessity for accurate voltage calibration has grown significantly with the spread of cutting-edge technologies like automation, artificial intelligence (AI), and the Internet of Things (IoT). Accurate and repeatable calibration processes are provided by automated calibration solutions, guaranteeing reliable operation of a variety of tools and apparatus.

By doing away with labor-intensive and error-prone manual calibration procedures, automation helps businesses save labor expenses and increase productivity. Businesses can increase throughput, turnaround times, and operational efficiency by putting automated voltage calibration solutions into place.

The growing need for adherence to industry standards and laws is one of the factors propelling the use of automated calibration systems. Accurate calibration of voltage measurement devices is required by stringent regulations in a number of industries, including electronics, healthcare, automotive, and aerospace. By offering written proof of calibration results, automated calibration solutions guarantee adherence to legal requirements and lower the possibility of expensive fines or product recalls.

Technological developments like the incorporation of remote monitoring features and cloud-based calibration software have increased the affordability and accessibility of automated calibration solutions for companies of all kinds. These developments reduce downtime and increase equipment uptime by enabling proactive maintenance scheduling, remote troubleshooting, and real-time monitoring of calibration procedures.

Segmental Insights

Device Type Insights

In 2023, the Bench Type category had the biggest market share. Usually, bench-type voltage calibrators are made with extreme accuracy and precision in mind. They are frequently employed in lab settings where accurate instrument calibration is essential. These calibrators are appropriate for applications requiring a high degree of calibration certainty because they frequently offer precise and steady voltage references.

Because of its versatility, bench-type calibrators are frequently used to calibrate a variety of instruments, such as oscilloscopes, multimeters, and other voltage-sensitive devices. Numerous features and functionalities that address a range of calibrating requirements can be included thanks to their design.

Advanced features like numerous output channels, programmability, and compatibility with various voltage ranges are frequently included in bench-type calibrators. Because of these characteristics, they may be used to calibrate a wide range of intricate electronic devices.

Bench-type calibrators are made to produce results that are steady and reliable over time. This stability is essential for guaranteeing the calibration process' dependability, particularly in settings requiring frequent and accurate readings.

Bench-type calibrators are the preferred option in laboratory environments, which offer regulated conditions and a dedicated workspace. These calibrators' stationary design fits in nicely with the needs of a lab environment.

Regional Insights

In 2023, North America's market share was the greatest. The industrial landscape of North America is highly developed and technologically advanced. Many companies in the area depend significantly on accurate voltage instrument calibration for peak performance and adherence to legal requirements. Accurate voltage calibrators are necessary for industries including electronics, telecommunications, automotive, and aerospace to guarantee the dependability and security of their operations and products. Consequently, North America has a high demand for voltage calibrators, which propels market expansion and maintains the region's leadership.

Research and development (R&D) and innovation are highly valued in North America. Some of the top businesses and research institutes in the world that focus on instrument calibration technologies are located in this region. These organizations consistently make investments in research and development to create sophisticated voltage calibrators with improved functionality, accuracy, and precision. Furthermore, partnerships among government agencies, business, and academia promote the sharing of information and experience, which propels advancements in the voltage calibration sector. Consequently, North American producers have a competitive advantage in the worldwide market since they are at the forefront of technological breakthroughs in the design and production of voltage calibrators.

North America's strong regulatory environment helps explain why the area dominates the voltage calibrator market. Calibration standards for voltage measurement devices are established and enforced in large part by regulatory organizations like the Standards Council of Canada (SCC) and the National Institute of Standards and Technology (NIST) in the United States. Businesses that operate in regulated industries including utilities, healthcare, and energy must adhere to these norms. In order to improve their competitiveness in the market and encourage global customer adoption, North American manufacturers give top priority to the research and manufacturing of voltage calibrators that either meet or surpass these strict regulatory criteria.

The distribution and maintenance of voltage calibrators are supported by a firmly established infrastructure in North America. The region boasts a vast network of distributors, dealers, and service providers specializing in calibration equipment, ensuring easy accessibility and availability of voltage calibrators to end-users across various industries. Additionally, to further increase client happiness and loyalty, North American manufacturers provide extensive after-sales support, including calibration services, maintenance, and technical assistance.

North America's economic stability and favorable business environment contribute to the region's dominance in the voltage calibrator market. The region offers a conducive ecosystem for investment, entrepreneurship, and business growth, attracting both domestic and international players to establish their presence in the market. Furthermore, industry-wide mergers, acquisitions, and strategic alliances support market consolidation and the growth of the market share of North American businesses.

Download Free Sample Ask for Discount Request Customization

Recent Developments

- In March 2023, Beamex has unveiled a significant enhancement for its HART-enabled MC6 Advanced Field Calibrator and Communicator series. This enhancement, integrated into firmware version 4.40, rolled out in February 2023, empowers MC6 users to conduct the partial calibration of air-operated valves efficiently. With this update, users can now power up the valve controller, generate the input mA signal, and monitor the digital output signal seamlessly—all within a single device.

Key Market Players

- Fluke Corporation

- Yokogawa Test & Measurement Corporation

- Keysight Technologies Inc.

- Ametek Inc.

- Omega Engineering, Inc.

- PCE Deutschland GmbH

- Good Will Instrument Co., Ltd.

- Hioki E.E. Corporation

- Rohde & Schwarz GmbH & Co. KG

- Teledyne Technologies Inc.

|

By Component |

By Device Type |

By Application |

By Industry |

By Region |

|

|

|

|

|

Related Reports

- Gas Fired Boiler Market Size - By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 - 100 MMBtu/hr, > 100 - 250 MMBtu/...

- Europe Residential Boiler Market Size - By Technology (Condensing {Natural Gas, Oil, Electric}, Non-Condensing {Natural ...

- U.S. Boiler Market Size By Fuel (Natural Gas, Oil, Coal), Capacity, By Technology (Condensing, Non-Condensing), By Produ...

- Commercial Hot Water Boiler Market Size - By Fuel (Natural Gas, Oil, Coal, Electric), By Technology (Condensing, Non-Con...

- UK Commercial Boiler Market Size By Fuel (Natural Gas, Oil, Coal, Electric), By Capacity, By Technology (Condensing, Non...

- Residential Electric Boiler Market Size - By Voltage Rating (Low Voltage, Medium Voltage), Industry Analysis Report, Reg...

Table of Content

- 1. Executive Summary

- 1.1. Key Findings

- 1.2. Market Snapshot (Current Size and Growth Projections)

- 1.3. Future Outlook and Key Opportunities

- 2. Introduction to the Voltage Calibrator Market

- 2.1. What are Voltage Calibrators?

- 2.2. Importance of Voltage Calibrators in Various Industries

- 2.3. Types of Voltage Calibrators

- 2.3.1. Benchtop Calibrators

- 2.3.2. Portable/Handheld Calibrators

- 2.3.3. Multifunction Calibrators

- 2.4. Scope of the Report

- 3. Market Overview and Dynamics

- 3.1. Current Market Size and Valuation (2025: ~$0.8 Billion)

- 3.2. Historical Market Performance (2017-2024)

- 3.3. Market Dynamics

- 3.3.1. Drivers of Market Growth

- 3.3.1.1. Increasing Automation Across Industries

- 3.3.1.2. Expanding Electronics and Semiconductor Manufacturing

- 3.3.1.3. Growing Demand for Accurate Measurement, Testing, and Regulation

- 3.3.1.4. Stringent Regulatory Standards and Quality Assurance Requirements (e.g., ISO/IEC 17025)

- 3.3.1.5. Modernization and Digitalization of Power Grids

- 3.3.1.6. Proliferation of Advanced Consumer Electronics

- 3.3.1.7. Rise in Field-Based Maintenance Needs

- 3.3.2. Challenges and Restraints

- 3.3.2.1. High Initial Cost of Precision Calibrators

- 3.3.2.2. Complexity of Technological Integration

- 3.3.2.3. Limited Availability of Skilled Personnel

- 3.3.2.4. Competition from Alternative Measurement Technologies

- 3.3.3. Opportunities

- 3.3.3.1. Development of Multifunctional and Portable Calibrators

- 3.3.3.2. Integration of AI, IoT, and Cloud Connectivity

- 3.3.3.3. Expansion in Emerging Economies with Electrification Projects

- 3.3.3.4. Growth of Calibration as a Service (CaaS) Models

- 3.3.3.5. Increased Demand in Renewable Energy Sector

- 3.3.1. Drivers of Market Growth

- 4. Market Segmentation

- 4.1. By Product Type

- 4.1.1. Benchtop Calibrators

- 4.1.2. Portable/Handheld Calibrators (Dominant Segment ~60%)

- 4.1.3. Multifunction Calibrators

- 4.2. By Component

- 4.2.1. Products (Hardware)

- 4.2.2. Services (Calibration Services, Maintenance, Training)

- 4.3. By Application

- 4.3.1. Electrical Testing & Troubleshooting (Largest Segment)

- 4.3.2. Process Device Calibration (Transducers, Indicators, Controllers)

- 4.3.3. Research & Development

- 4.3.4. Quality Assurance & Control

- 4.3.5. Other Specific Applications (e.g., Power Grid Monitoring, Avionic Calibration)

- 4.4. By End-User Industry

- 4.4.1. Electronics & Semiconductor

- 4.4.2. Energy & Power (Utilities, Renewable Energy)

- 4.4.3. Automotive & Transportation

- 4.4.4. Aerospace & Defense

- 4.4.5. Telecommunications

- 4.4.6. Healthcare (Medical Device Testing)

- 4.4.7. Manufacturing & Process Industries

- 4.4.8. Research Laboratories & Academia

- 4.4.9. Other Industries

- 4.1. By Product Type

- 5. Regional Analysis

- 5.1. North America (Largest Market by Value - Driven by electronics manufacturing, high consumer electronics penetration, and industrial automation)

- 5.1.1. United States

- 5.1.2. Canada

- 5.2. Europe (Driven by stringent quality control regulations)

- 5.2.1. Germany

- 5.2.2. UK

- 5.2.3. France

- 5.2.4. Rest of Europe

- 5.3. Asia Pacific (Highest CAGR - Rapid industrialization, investments in smart grid, electronics, and electrical sectors)

- 5.3.1. China

- 5.3.2. India

- 5.3.3. Japan

- 5.3.4. South Korea

- 5.3.5. ASEAN Countries

- 5.3.6. Australia

- 5.4. Latin America (Emerging opportunities with infrastructure development)

- 5.5. Middle East & Africa (Gradual adoption in emerging markets)

- 5.1. North America (Largest Market by Value - Driven by electronics manufacturing, high consumer electronics penetration, and industrial automation)

- 6. Competitive Landscape

- 6.1. Market Share Analysis of Key Players (Moderately Concentrated - Fluke, WIKA, Ametek hold significant share)

- 6.2. Profiles of Major Companies

- 6.2.1. Fluke Corporation (Fluke Calibration)

- 6.2.2. Keysight Technologies Inc.

- 6.2.3. WIKA Alexander Wiegand SE & Co. KG

- 6.2.4. AMETEK Inc. (AMETEK Calibration)

- 6.2.5. Yokogawa Electric Corporation

- 6.2.6. Extech Instruments (FLIR Systems)

- 6.2.7. Time Electronics Ltd.

- 6.2.8. Transmille Ltd.

- 6.2.9. Additel Corporation

- 6.2.10. Beamex

- 6.2.11. OMEGA Engineering Inc.

- 6.2.12. Martel Electronics Corporation

- 6.2.13. PCE Holding GmbH

- 6.2.14. Other Prominent Players (e.g., Chauvin Arnoux, MEATEST, Nagman Instruments)

- 6.3. Recent Developments, Strategic Partnerships, and Acquisitions (e.g., new product launches, focus on advanced digital interfaces)

- 7. Technological Trends and Innovations

- 7.1. Development of Multifunctional and Multi-Parameter Calibrators

- 7.2. Integration of Digital Technology and Automation (DSP, automated calibration routines)

- 7.3. Portability and Handheld Units for Field Applications

- 7.4. Advanced Features: AI-driven Self-Calibration, IoT Integration, Blockchain-based Records

- 7.5. Augmented Reality (AR)-enabled Field Support

- 7.6. Focus on User-Friendliness and Intuitive Interfaces

- 8. Future Outlook and Projections (up to 2031/2032)

- 8.1. Forecasted Market Size and CAGR (Projected to reach ~$451.0 million by 2031 at 9.6% CAGR, or ~$1.5 Billion by 2032 at 7.3% CAGR)

- 8.2. Emerging Opportunities and Growth Pockets

- 8.3. Impact of Regulatory Evolution and Technological Advancements on Market Trajectory

- 8.4. Strategic Recommendations for Market Participants

- 9. Conclusion

Major Key Players

- Fluke Corporation (Fortive Corporation) (USA)

- Keysight Technologies, Inc. (USA)

- Rohde & Schwarz GmbH & Co. KG (Germany)

- OMEGA Engineering (Spectris plc) (USA)

- Chauvin Arnoux Group (France)

- Hioki E.E. Corporation (Japan)

- Keithley Instruments (Tektronix, Inc. / Danaher Corporation) (USA)

- Yokogawa Electric Corporation (Japan)

- GE Measurement & Control (Baker Hughes) (USA)

- Time Electronics Ltd. (UK)

Manufacturers Key Players

- Fluke Corporation (Fortive Corporation) (USA)

- Keysight Technologies, Inc. (USA)

- Rohde & Schwarz GmbH & Co. KG (Germany)

- OMEGA Engineering (Spectris plc) (USA)

- Chauvin Arnoux Group (France)

- Hioki E.E. Corporation (Japan)

- Keithley Instruments (Tektronix, Inc. / Danaher Corporation) (USA)

- Yokogawa Electric Corporation (Japan)

- GE Measurement & Control (Baker Hughes) (USA)

- Time Electronics Ltd. (UK)

- Ametek, Inc. (USA)

- Megger (Avo International Ltd.) (UK)

- Metrel d.d. (Slovenia)

- Gossen Metrawatt GmbH (Germany)

- Sifam Tinsley Instrumentation Ltd. (UK/India)

- Transmille Ltd. (UK)

- Condec (USA)

- ISOTECH Ltd. (UK)

- Beamex Oy Ab (Finland)

FAQ'S

For a single, multi and corporate client license, the report will be available in PDF format. Sample report would be given you in excel format. For more questions please contact:

Within 24 to 48 hrs.

You can contact Sales team (sales@marketinsightsresearch.com) and they will direct you on email

You can order a report by selecting payment methods, which is bank wire or online payment through any Debit/Credit card, Razor pay or PayPal.

Discounts are available.

Hard Copy