Printed Batteries Market

Printed Batteries Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Components (Anode, Cathode, Electrolyte, Collectors), By Application (Radio-Frequency Sensing, Data Recording System, Others), By End User Industry (Consumer Electronics, Wearable Devices, Pharmaceuticals and Healthcare, Packaging, Others), By Region, By Competition 2018-2028

Published Date: May - 2025 | Publisher: MIR | No of Pages: 320 | Industry: Power | Format: Report available in PDF / Excel Format

View Details Buy Now 2890 Download Free Sample Ask for Discount Request Customization| Forecast Period | 2024-2028 |

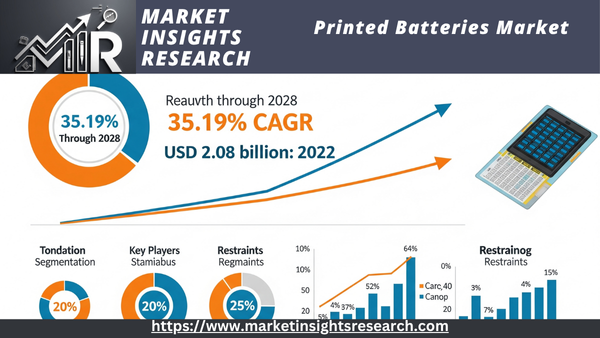

| Market Size (2022) | USD 2.08 Billion |

| CAGR (2023-2028) | 35.19% |

| Fastest Growing Segment | Radio-Frequency Sensing |

| Largest Market | North America |

Market Overview

Global Printed Batteries Market was valued at USD 2.08 billion in 2022 and is anticipated to project robust growth in the forecast period with a CAGR of 35.19% through 2028.

Download Free Sample Ask for Discount Request Customization

The main benefit of printed batteries is their capacity to adapt to unusual form factors, which makes them perfect for incorporation into gadgets where conventional batteries would not be feasible. Continuous technological development, the need for portable and adaptable power sources, and the global movement toward ecologically friendly energy solutions are the main factors propelling this market.

The market for printed batteries is expected to grow significantly as production methods improve and innovation keeps up, providing solutions to meet the various power requirements of contemporary electronics and new technologies while creating chances for more economical and ecologically friendly energy storage.

Key Market Drivers

Technological Advancements and Miniaturization

The continuous trend of miniaturization and a relentless wave of technological advancements are driving the global printed batteries market. Conventional batteries are frequently heavy and stiff, which makes it difficult to incorporate them into wearables and other electronic devices. Conversely, the highly adaptable nature of printed batteries allows for their production in a variety of sizes and shapes, making them ideal for tiny, portable electronics. This trend is particularly important in sectors like healthcare, where wearable medical devices require dependable and portable power sources. Manufacturers of printed batteries are constantly enhancing energy density, performance, and durability as technology advances, which propels the market's expansion.

Increasing Demand for Wearable Electronics

The global market for printed batteries is significantly influenced by the rising popularity of wearable technology, including smartwatches, fitness trackers, and augmented reality glasses. These gadgets need flexible, lightweight power sources that can adapt to their design and deliver consistent, long-lasting power. Because printed batteries can be easily incorporated into wearable designs, they are ideal for this use case. The need for printed batteries in these applications is anticipated to increase significantly as consumer interest in smart connectivity, fitness and health monitoring, and other related fields continues to expand.

Download Free Sample Ask for Discount Request Customization

Expanding Internet of Things (IoT) Ecosystem

Another significant factor propelling printed batteries is the growth of the Internet of Things (IoT) ecosystem. From smart cities and homes to industrial automation and agriculture, IoT devices are becoming more and more common in a variety of sectors. A lot of Internet of Things devices are tiny, portable, and need long-lasting power sources. These gadgets may function without the need for frequent battery replacements thanks to printed batteries, which offer a flexible powering solution. As the IoT market expands, we anticipate a growing need for printed batteries to power these devices.

Environmental Concerns and Sustainability

The use of printed batteries is being fueled by environmental concerns and the increased focus on sustainability. We can produce printed batteries using more environmentally acceptable materials, making them a more environmentally responsible option than traditional batteries that often contain harmful elements. Furthermore, because they are lightweight and flexible, electronic devices have a smaller total environmental impact. It is anticipated that demand for sustainable energy solutions, such as printed batteries, would rise as businesses and consumers grow more aware of their environmental impact.

Emerging Applications in Healthcare

The global market for printed batteries has a bright future in the healthcare industry. Reliable power sources are necessary as medical gadgets get smaller and more advanced. One benefit of printed batteries is their ability to be customized to fit the designs of medical devices, which makes them appropriate for use in drug delivery systems, implanted devices, and medical patches. The healthcare sector is expected to be a major driver of printed battery adoption due to an older population and an increasing emphasis on remote patient monitoring.

Floor and Defense Applications

The market for printed batteries is growing as a result of the defense and floor industries. These industries require energy-efficient and lightweight power solutions for a variety of uses, such as unmanned aerial vehicles (UAVs), sensors, and communication equipment. Because of their adaptability and customization, printed batteries are ideally suited to satisfy the particular power needs of military and floor applications. The need for printed batteries in these industries is expected to rise significantly as defense technologies and the commercial space industry develop further.

In summary, the demand for wearables and Internet of Things devices, technical breakthroughs, sustainability issues, healthcare applications, and aerospace and defense requirements are all driving the global printed batteries market. Together, these factors foster the market's potential for sustained expansion and innovation in printed batteries, which could completely change how we power our electronic devices going forward.

Download Free Sample Ask for Discount Request Customization

Government Policies are Likely to Propel the Market

Research and Development Incentives

Innovation and competitiveness are greatly enhanced by government policies that provide incentives for research and development (R&D) activities in the worldwide printed batteries market. These incentives, which encourage businesses engaged in the development of printed battery technology, can take many different forms, including as tax credits, grants, and subsidies.

Promoting private-sector R&D investment is one of the main goals of such programs, as this eventually results in improvements in battery performance, manufacturing techniques, and materials. Governments can encourage technological advancements and position their nations as leaders in this developing sector by providing tax breaks and financial assistance to businesses involved in printed battery research and development.

By attracting talent, fostering the expansion of a knowledge-based economy, and providing high-skilled jobs, these incentives not only help firms but also advance economic growth. They can also hasten the commercialization of novel printed battery solutions, increasing their accessibility across a range of industries, including consumer electronics, healthcare, and transportation.

Environmental Regulations and Sustainability Standards

Governments everywhere are enacting laws and guidelines to address the effects of battery manufacture, use, and disposal as they become more aware of how important environmental sustainability is. These regulations seek to encourage the use of greener and more sustainable technologies while reducing the environmental impact of batteries, particularly printed batteries.

These policies' salient features could include

Limitations on Hazardous MaterialsTo reduce dangers to the environment and public health, governments may place restrictions on the use of hazardous materials like lead, cadmium, and mercury in the manufacturing of batteries.

Requirements for Battery Recycling and DisposalLaws may require batteries to be disposed of and recycled responsibly, which would incentivize battery producers to create recyclable batteries.

Energy Efficiency StandardsTo cut down on energy waste and encourage the adoption of energy-efficient technology, governments might establish energy efficiency goals for batteries, including printed batteries.

Eco-labeling and Certification systemsTo assist consumers in recognizing and selecting battery goods that are ecologically friendly, governments may set up certification systems or eco-labels.

By putting these regulations into effect, governments foster innovation in sustainable battery technologies while simultaneously safeguarding the environment. In order to ensure that the market shifts towards a more sustainable future, manufacturers are encouraged to create cleaner and greener printed battery solutions that adhere to these regulations.

Intellectual Property Protection

Policies protecting intellectual property (IP) are essential for encouraging investment and innovation in the worldwide market for printed batteries. Governments may foster an atmosphere that encourages businesses and researchers to advance and safeguard their printed battery technology intellectual property.

These rules cover a wide range of topics, such as trade secrets, trademarks, copyrights, and patents. They offer legal frameworks to protect innovators' intellectual property rights, granting them temporary exclusivity over their breakthroughs and creations. Knowing that their efforts will be safeguarded and that they may be able to make money off of their inventions, this exclusivity incentivizes businesses to invest in research and development.

Good IP protection laws also encourage cooperation between national and international printed battery sector stakeholders and draw in foreign direct investment. Governments may boost economic growth, encourage innovation, and establish their nations as centers for advanced battery technologies by creating an atmosphere that values and safeguards intellectual property.

Safety and Certification Standards

Government-established safety and certification requirements are crucial for guaranteeing the dependability and security of printed batteries used in a variety of applications. These regulations establish the standards that producers must fulfill to ensure the environmental and consumer safety of their goods.

Important elements of printed battery safety and certification regulations could include

Requirements for Testing and ComplianceGovernments may mandate that producers carry out stringent testing and prove that they are adhering to safety regulations unique to printed batteries.

Labeling and DocumentationTo educate users and regulators, policies may require that battery specifications, such as voltage, capacity, and safety measures, be clearly labeled and documented.

Quality Assurance and production PracticesTo guarantee constant product quality and safety, regulations might cover production procedures, quality control, and traceability.

Procedures for Recall and ReportingGovernments may set up protocols to help manufacturers recall products and swiftly report safety-related problems.

Governments can promote market access, safeguard customers from any hazards connected with inferior or dangerous products, and foster trust in printed battery technology by enacting strict safety and certification regulations. These regulations support the printed battery industry's general expansion and legitimacy.

Trade and Export Controls

The global market for printed batteries is greatly impacted by government laws pertaining to trade and export restrictions, particularly when it comes to international cooperation and sales. Global competitiveness and market dynamics may be impacted by these rules' effects on the import and export of printed batteries and associated technologies.

Governments have the authority to enact trade laws that

Regulate ExportsIn order to protect national security interests or stop the spread of sensitive technologies, governments may regulate the export of printed battery technologies.

Encourage Export GrowthOn the other hand, certain governments might aggressively encourage the export of printed batteries and associated goods by offering trade promotion initiatives, export incentives, and assistance with market access.

Encourage Cross-Border CollaborationBy lowering trade barriers and promoting international cooperation, policies can promote cross-border cooperation in R&D and manufacturing.

Each government's strategic goals will determine how these policies affect the printed battery market. While some may place more emphasis on international collaboration and knowledge transfer, others may favor the expansion of the native industry. In addition to addressing national interests and the dynamics of international commerce, effective trade and export policies can improve market access and competitiveness.

Investment Incentives and Subsidies

The expansion and competitiveness of the worldwide printed battery industry can be strongly impacted by government policies that offer financial incentives and subsidies. These regulations are intended to draw capital to the infrastructure, R&D, and manufacturing facilities associated with the fabrication of printed batteries.

Important components of subsidies and incentives for investment could be

Tax incentivesBusinesses that manufacture printed batteries, conduct research and development, or set up production facilities may be eligible for tax incentives from governments.

Grants and SubsidiesBusinesses in the printed battery sector can receive financial grants and subsidies to help them with costs associated with development, manufacturing, and growth.

Infrastructure DevelopmentPolicies might concentrate on enhancing the testing facilities, transportation networks, and specialized research institutions that are essential to the manufacturing of printed batteries.

Workforce DevelopmentTo guarantee a trained workforce able to satisfy the demands of the printed battery industry, governments might fund workforce development initiatives.

These policies aim to reduce the financial barriers to entry and stimulate investment, job creation, and economic growth within the printed battery sector. By drawing in both domestic and foreign investors interested in the nascent printed battery sector, they also help a nation become more competitive in the global market.

In conclusion, the worldwide market for printed batteries is significantly shaped by government policy. The industry's growth, innovation, and competitiveness are influenced by policies pertaining to R&D incentives, environmental sustainability, intellectual property protection, safety and certification standards, trade and export regulations, and investment incentives. Governments will have a significant influence on the advancement and uptake of printed batteries globally as they continue to modify and improve these regulations.

Key Market Challenges

Energy Density and Performance Optimization

The need to continuously increase energy density and overall performance is one of the biggest issues facing the worldwide printed battery market. Although printed batteries have several benefits, such as adaptability and customization, they frequently fall short of conventional battery technologies in terms of power output and energy storage capacity.

The quantity of energy that a battery can store per unit of weight or volume is known as its energy density. Higher energy density is essential in many applications, especially in consumer electronics and electric cars, as it prolongs battery life and helps reduce the devices' size and weight. The energy density of traditional lithium-ion batteries has proven difficult for printed batteries, which are made of thin, flexible materials.

Improvements in chemistry, materials science, and manufacturing processes are necessary to increase the energy density of printed batteries. To increase energy storage capacity, researchers are actively working on creating new materials such solid-state electrolytes and high-capacity electrode materials. Furthermore, it's critical to optimize printing procedures to produce battery layers that are thinner and more densely packed.

It can be difficult to strike a balance between increasing energy density and other important considerations like cost-effectiveness, safety, and cycle life. To satisfy the varied demands of distinct applications, a careful trade-off between multiple performance indicators is necessary. Resolving this issue continues to be a primary focus for manufacturers and researchers as the market needs printed batteries that are stronger and last longer.

Scalability and Cost Reduction

Two interrelated issues that could have a big influence on the expansion and uptake of printed batteries globally are scalability and cost reduction. Achieving mass production at a reasonable price point is still a significant challenge, despite the potential for low-cost manufacturing and design freedom offered by printed batteries.

Costs of MaterialsConductive inks, electrolytes, and substrates are among the specialty materials that are frequently used in printed batteries. These materials can be costly, especially if they are made in tiny amounts. Manufacturers must create cost-effective sourcing plans and look into substitute materials that are more reasonably priced without sacrificing performance in order to cut expenses.

Manufacturing ProcessesComplexities and cost inefficiencies may arise when production is scaled up from laboratory to mass scale. Manufacturers must make investments in cutting-edge printing and assembly machinery that can lower production costs while maintaining high quality and consistency.

Quality ControlIt can be difficult to guarantee constant quality when printing a lot of batteries. In addition to raising production costs, defective batteries can raise safety concerns. Maintaining dependability and reducing flaws require the use of strong quality control procedures.

Economies of ScaleLowering the cost of printed batteries per unit requires achieving economies of scale. Manufacturers can profit from reduced production costs and increased manufacturing process efficiency as demand rises.

Competitive PricingIn order for printed batteries to be accepted by the market, their price must be comparable to that of conventional battery technologies. Cost-effective solutions are necessary for broad adoption because both organizations and consumers are price sensitive.

A multidisciplinary strategy integrating developments in materials science, engineering, and industrial methods is needed to address these issues. To spur innovation and optimize the production and supply chain of printed batteries, cooperation between government agencies, business, and academia is crucial.

Furthermore, manufacturer competition is expected to increase as the printed battery market develops further. A greater variety of applications may find printed batteries more affordable as a result of this rivalry. To realize its full potential, the worldwide printed batteries market must overcome the crucial obstacle of finding the ideal balance between cost reduction and upholding performance and safety regulations.

Segmental Insights

Components Insights

The Anode sector is anticipated to continue to hold the biggest market share during the projection period, having done so in 2022. Together with the cathode, the anode is one of a battery's two principal electrodes. It is essential to the electrochemical processes that take place during a battery's cycles of charging and discharging. In particular, during discharge, ions go through the electrolyte from the anode to the cathode, whereas electrons enter the battery through the anode. The anode is a crucial part of battery operation since this electron flow is necessary for producing electrical energy. The energy storage capacity of a battery is greatly impacted by the anode material selection. The efficiency with which electrical energy is stored and delivered by printed batteries is directly impacted by advancements in anode materials, such as the creation of high-capacity materials like lithium-based compounds and sophisticated carbon architectures. Longer-lasting and more potent batteries are the result of higher energy density anode materials, which is a critical component in the highly competitive global battery business. Anode materials need to work well with the cathode, electrolyte, and collectors—the other parts of printed batteries. The battery's overall performance, safety, and dependability may be impacted by the anode material selection. Manufacturers and researchers work to identify anode materials that are stable and compatible with the printed battery system, in addition to having a high energy density. Improvements in anode materials and technology are frequently given top priority in the battery industry's ongoing research and development initiatives. These developments are meant to increase battery safety, cycle life, and performance. In order to create printed batteries with rapid-charging capabilities—which are greatly desired in many applications—researchers are working to create anode materials that can support faster charge and discharge rates. More effective and high-performance energy storage solutions are needed as the market for printed batteries in wearables, Internet of Things devices, and medical wearables continues to expand. At the vanguard of these advancements are anodes, which propel breakthroughs that allow printed batteries to satisfy the various power needs of contemporary electronic devices.

Application Insights

With the most market share in 2022, the Radio-Frequency Sensing sector is expected to develop rapidly throughout the course of the forecast period. Many businesses, including supply chain management, retail, logistics, and healthcare, employ radio-frequency sensing (RFID) technology to track and identify goods. Their dominance in the market may be attributed to the strong demand for printed battery-powered RFID tags and sensors because of their versatility, adaptability, and flexibility. The power needs and performance requirements of RFID applications must be satisfied by printed batteries. They might be chosen over alternative power sources if they provide dependable and steady power to RFID tags while being reasonably priced and simple to incorporate. Because printed batteries can adapt to many sizes and shapes, they are a good fit for RFID tags, which frequently need to be tiny and discrete. Compact RFID tags may become dominant in this particular use if printed batteries can power them effectively. The use of printed batteries in RFID applications may be further encouraged if there have been notable developments in printing technology that improve the quality and production efficiency of printed batteries. The adoption of printed batteries in sectors with stringent compliance requirements would be facilitated if they satisfied the applicable safety and regulatory criteria for RFID applications.

Regional Insights

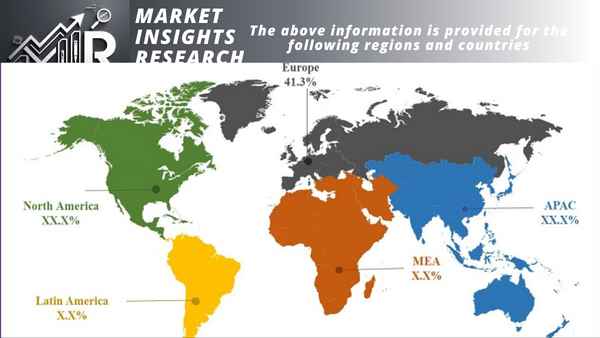

In 2022, North America accounted for more than 40% of the worldwide printed battery market, making it the largest market. Several major companies in the printed battery industry, including Enfucell, Imprint Energy, and Planar Energy Devices, are based in the region. The market for printed batteries is expanding in North America due to the early acceptance of new technologies and the rising demand for wearable electronics and Internet of Things devices.

With more than 30% of the global printed battery market in 2022, Europe was the second-largest market. Cymbet and Printed Electronics Limited are two of the major companies in the printed batteries sector that are based in the region. The European printed battery market is expanding due to the rising need for smart packaging and medical products.

With a compound annual growth rate (CAGR) of more than 50% over the projection period, Asia Pacific is the printed battery market with the quickest rate of expansion. Wearable technology and Internet of Things devices are becoming more and more popular in the region's emerging economies, which include China, India, and South Korea. The market for printed batteries in Asia Pacific is also expanding as a result of the growing popularity of electric vehicles.

Download Free Sample Ask for Discount Request Customization

Recent Developments

- In March 2023, Ilika plc received a USD 21.22 million investment from Innovate UK to develop and commercialize its solid-state Stereax batteries.

- In February 2023, Enfucell raised USD10.61 million in Series B funding to scale up production of its printed batteries.

- In January 2023, Imprint Energy raised USD 100 million in Series D funding to expand the production of its printed batteries for wearable devices and other applications.

- In November 2022, Printed Electronics Limited received a USD2.12 million investment from the UK government to develop printed batteries for smart packaging.

- In September 2022, BlueSpark Technologies raised USD 25 million in Series C funding to develop and commercialize its printed batteries for IoT devices.

Key Market Players

- Ilika plc

- Enfucell Oy

- Imprint Energy Inc

- Printed Electronics Limited

- BlueSpark Technologies Inc

- Cymbet Corporation

- NanoGraf Corporation

- Thin Film Electronics ASA

- Inuru

- Skeleton Technologies GmbH

|

By Components |

By Application |

By End User Industry |

By Region |

|

|

|

|

Related Reports

- Europe Steam Boiler Market - By Capacity, By Fuel (Natural Gas, Oil, Coal), By Technology (Condensing, Non-Condensing), ...

- Electric Boiler Market Size By Voltage Rating (Low, Medium), By Application (Residential, Commercial, Industrial, Food P...

- Europe Boiler Market By Fuel (Natural Gas, Oil, Coal, Electric), By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 ...

- Boiler Market Size - By Fuel (Natural Gas, Oil, Coal, Electric), By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 ...

- Residential Boiler Market Size By Technology (Condensing {Natural Gas, Oil, Electric}, Non-Condensing {Natural Gas, Oil,...

- Commercial Electric Boiler Market - By Voltage Rating (Low Voltage, Medium Voltage), By Capacity, By Product (Hot Water,...

Table of Content

-

Executive Summary

-

1.1 Market Snapshot

-

1.2 Key Developments and Trends

-

1.3 Strategic Recommendations

-

-

Introduction

-

2.1 Report Objectives and Scope

-

2.2 Research Methodology

-

2.3 Definitions and Battery Classification

-

-

Market Overview

-

3.1 What Are Printed Batteries?

-

3.2 Evolution and Benefits Over Conventional Battery Technologies

-

3.3 Application Scenarios in Next-Gen Electronics and IoT Devices

-

3.4 Value Chain and Manufacturing Workflow

-

-

Market Dynamics

-

4.1 Drivers

-

4.1.1 Surge in Flexible and Wearable Electronics

-

4.1.2 Growth in Medical Patches, Smart Labels, and RFID Tags

-

4.1.3 Advances in Roll-to-Roll and 3D Printing Technologies

-

-

4.2 Restraints

-

4.2.1 Low Energy Density Compared to Conventional Batteries

-

4.2.2 Scalability and Mass Production Barriers

-

-

4.3 Opportunities

-

4.3.1 Integration into Smart Packaging and Disposable Devices

-

4.3.2 Developments in Eco-Friendly, Biodegradable Materials

-

-

4.4 Challenges

-

4.5 Porter’s Five Forces Analysis

-

-

Technology Landscape

-

5.1 Zinc-Based Printed Batteries

-

5.2 Lithium-Based Thin-Film and Solid-State Batteries

-

5.3 Graphene and Carbon-Based Electrodes

-

5.4 Substrate Innovations (Plastic, Paper, Textile)

-

5.5 Printing Techniques: Screen Printing, Inkjet, Gravure

-

-

Market Segmentation

-

6.1 By Battery Type

-

6.1.1 Rechargeable

-

6.1.2 Non-Rechargeable

-

-

6.2 By Voltage Rating

-

6.2.1 Below 1.5V

-

6.2.2 1.5V–3V

-

6.2.3 Above 3V

-

-

6.3 By Application

-

6.3.1 Wearables

-

6.3.2 Smart Packaging

-

6.3.3 Medical Devices and Patches

-

6.3.4 IoT Sensors and Electronics

-

6.3.5 Toys, Cards, and Flexible Displays

-

-

-

Regional Analysis

-

7.1 North America

-

7.2 Europe

-

7.3 Asia-Pacific

-

7.4 Latin America

-

7.5 Middle East & Africa

-

-

Market Size and Forecast (2020–2030)

-

8.1 Revenue and Volume Forecast by Region and Segment

-

8.2 Cost Trends and Pricing Models

-

8.3 Adoption Rates by Industry Sector

-

-

Competitive Landscape

-

9.1 Market Share and Technology Positioning

-

9.2 Company Profiles

-

9.2.1 Enfucell

-

9.2.2 Imprint Energy

-

9.2.3 Blue Spark Technologies

-

9.2.4 Jenax

-

9.2.5 Samsung SDI (Flexible/Printed Innovations)

-

9.2.6 Others

-

-

9.3 R&D Pipelines, IP Analysis, and Strategic Collaborations

-

-

Regulatory and Environmental Framework

-

10.1 Safety and Transport Standards for Printed Batteries

-

10.2 E-Waste and End-of-Life Management Policies

-

10.3 Biocompatibility and Certification in Medical Applications

-

-

Innovation and Future Outlook

-

11.1 Printed Energy Storage for Smart Textiles and Skin Electronics

-

11.2 Sustainable Printed Power for Disposable IoT

-

11.3 Integration with Flexible Displays and Low-Power Electronics

-

-

Conclusion and Strategic Outlook

-

Appendices

-

13.1 Glossary

-

13.2 Research Methodology

-

13.3 References and Sources

To get a detailed Table of content/ Table of Figures/ Methodology Please contact our sales person at ( chris@marketinsightsresearch.com )

FAQ'S

For a single, multi and corporate client license, the report will be available in PDF format. Sample report would be given you in excel format. For more questions please contact:

Within 24 to 48 hrs.

You can contact Sales team (sales@marketinsightsresearch.com) and they will direct you on email

You can order a report by selecting payment methods, which is bank wire or online payment through any Debit/Credit card, Razor pay or PayPal.

Discounts are available.

Hard Copy