Industrial Battery Recycling Market

Industrial Battery Recycling Market – Global Industry Size, Share, Trends, Opportunity, and Forecast Segmented By Chemistry (Lead, Nickel, Cobalt, Lithium, and other Metals), By Battery Type (Lead-Acid Batteries, Nickel-Cadmium Batteries, Nickel Metal Hydride Batteries, and Lithium-Ion Batteries), By Region, Competition 2018-2028

Published Date: May - 2025 | Publisher: MIR | No of Pages: 320 | Industry: Power | Format: Report available in PDF / Excel Format

View Details Buy Now 2890 Download Free Sample Ask for Discount Request Customization| Forecast Period | 2024-2028 |

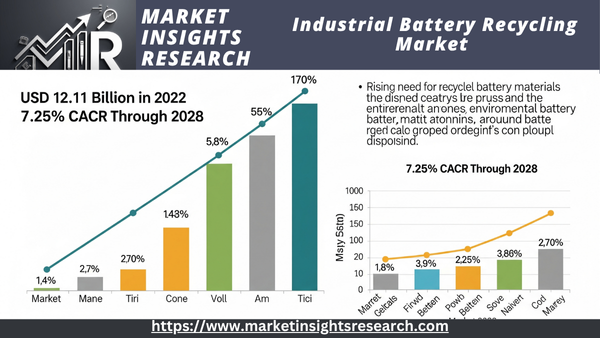

| Market Size (2022) | USD 12.11 Billion |

| CAGR (2023 | 7.25% |

| Fastest Growing Segment | Lead |

| Largest Market | Asia Pacific |

Market Overview

The market reached a valuation of USD 12.11 billion in 2022. Future outlook suggests substantial expansion, forecasting a Compound Annual Growth Rate (CAGR) of 7.25% through 2028.

Download Free Sample Ask for Discount Request Customization

Key Market Drivers

Driven by a mix of technological developments, rising demand for clean energy solutions, and a growing awareness of the environmental and safety benefits connected with dual carbon batteries, the worldwide Industrial Battery Recycling market is seeing major increases and innovation in recent years. This paper investigates the main causes of the Industrial Battery Recycling market's growth and offers an understanding of the elements causing its quick development.

Advanced energy storage systems called dual carbon batteries—also called dual carbon capacitors or dual carbon supercapacitors—use carbon-based materials for both the anode and cathode. Whereas conventional lithium-ion batteries depend on lithium-based materials for one electrode, dual carbon batteries use carbon's special qualities to provide multiple benefits. These benefits have helped them to take center stage in the world energy storage scene. Main Drivers of the World Industrial Battery Recycling Market In the battery business, safety has always taken center stage. A safer substitute garnering interest is dual carbon batteries, with their lower danger of thermal runaway and fire hazards than lithium-ion batteries. Industries and consumers are seeking safer energy storage solutions as safety rules get stricter. The demand for clean energy solutions has grown faster as sustainability and environmental preservation take center stage worldwide. Made mostly of carbon, dual carbon batteries are said to be more environmentally friendly than lithium-ion batteries, which depend on rare and highly demanding resources. Their acceptance is much influenced by this congruence with sustainability aims. Expanding renewable energy sources, including solar and wind, needs effective energy storage systems to balance demand and supply. Fast charging and discharging features of dual carbon batteries make them perfect for storing solar energy and solving grid instability problems. The automobile sector is changing fundamentally toward electric cars. For EV makers trying to maximize performance and safety while lowering charging times, dual carbon batteries' fast charging capacity, long lifespan, and safety features offer promise. The Industrial Battery Recycling industry is mostly driven by consumer electronics such as laptops and cellphones' demand for faster-charging and longer-lasting batteriesDevices that can remain running for extended periods and quickly recharge are becoming more and more important to consumers.

Industrial and IoT Battery Types

Industries and the Internet of Things (IoT) sector need dependable and long-lasting energy storage solutions. The resilience and power density of dual carbon batteries make them well-suited for diverse industrial applications and the expanding network of IoT devices.

Continuous research and development in the realm of dual carbon batteries have yielded enhancements in performance, cost reduction, and scalability. As the technology evolves, it becomes more economically feasible, further propelling market growth.

Disruptions in the global supply chain for essential materials, particularly following the COVID-19 pandemic, have encouraged industries to investigate alternative technologies less dependent on scarce or geopolitically sensitive resources. Dual carbon batteries present a way to lessen this reliance.

As more entities enter the Industrial Battery Recycling market, competition is intensifying. This often spurs innovation, cost reductions, and wider market adoption as companies aim to distinguish themselves and gain market share.

Governments globally are encouraging the adoption of clean energy technologies, including energy storage solutions. Subsidies, incentives, and policies focused on lowering greenhouse gas emissions and promoting energy efficiency establish a favorable landscape for dual carbon batteries.

The global Industrial Battery Recycling market is experiencing swift expansion, fueled by a convergence of elements from safety considerations and environmental sustainability to the growing need for energy storage solutions across various sectors. As the technology continues to mature and address its challenges, dual carbon batteries hold the promise of playing a crucial role in the shift towards cleaner, more efficient energy systems, benefiting industries, consumers, and the planet collectively.

While obstacles persist, ongoing research, innovation, and market competition are likely to drive further progress and broaden the adoption of dual carbon batteries in the years ahead.

Key Market Challenges

Download Free Sample Ask for Discount Request Customization

Scale-Up Challenges

Industrial Battery Recycling production's scalability still presents a difficulty. The manufacturing techniques for dual carbon batteries must be maximized for mass production if we want to rival proven technologies like lithium-ion batteries. Although twin carbon batteries have a lower energy density compared to some other energy storage systems, they excel in power density. This restriction could limit their application in battery types with great energy storage capacity. Wide-ranging acceptance depends on cost parity with current battery technologies. Reducing the cost of dual carbon batteries will depend mostly on developments in materials, manufacturing processes, and economies of scale. The market for Industrial Battery Recycling is still somewhat small; thus, awareness among possible consumers and investors has to rise. Key roles will be played by knowledge of the advantages and battery kinds as well as by education. Development and acceptance of regulatory criteria and certifications will help to guarantee the quality and safety of dual carbon batteries. In sectors like automobile and aviation especially, this is crucial.

Driven by elements including safety issues, sustainability, and the demand for effective energy storage solutions, the worldwide Industrial Battery Recycling market is seeing fast expansion and innovation. Like any developing technology, twin carbon batteries do, however, present a variety of issues that need to be resolved if they are to reach their greatest potential. The main obstacles confronting the worldwide Industrial Battery Recycling market will be discussed in this paper together with some chances for conquering them. Advanced energy storage systems called dual carbon batteries—also called dual carbon capacitors or dual carbon supercapacitors—use carbon-based materials for both the anode and cathode. Among other benefits over conventional lithium-ion batteries, this technology provides improved safety, environmental sustainability, and faster charging capability.

Energy Density & Scalability

One of the primary challenges for dual carbon batteries is their energy density. While they excel in power density, which enables quick charging and discharging, their energy density (the amount of energy stored per unit of weight or volume) is generally lower than that of lithium-ion batteries. This limitation makes dual carbon batteries less suitable for Battery Types requiring high energy storage capacities, such as long-range electric vehicles (EVs). Scalability remains a critical challenge. Industrial Battery Recycling must optimize manufacturing processes for mass production to compete with well-established battery technologies like lithium-ion. Scaling up production while maintaining quality and cost-effectiveness is a complex task that requires substantial investment and innovation.

Key Market Trends

Advancements in Materials Science

Researchers and manufacturers are constantly investigating advanced carbon materials to boost the performance of dual carbon batteries. This includes creating novel carbon composites, nanostructured materials, and carbon allotropes, which can enhance energy density and charge-discharge efficiency.

A key trend in the Industrial Battery Recycling market centers on increasing energy density. While these batteries shine in power density, efforts are in progress to improve their energy storage capacity, making them more appropriate for applications needing longer-range electric vehicles and larger energy storage systems.

Download Free Sample Ask for Discount Request Customization

Fast Charging and High-Power Battery Types

For Battery Types needing quick charging and discharging, such as electric automobiles and grid stability, dual carbon batteries are ideal. This trend fits the increasing demand in many different fields for fast and effective energy storage technologies. Combining twin carbon batteries with other energy storage systems, such as flow batteries or lithium-ion batteries, is becoming more and more popular. This hybrid technique offers flexibility and efficiency by allowing enhanced energy density and the best performance for particular Battery Types. In the Industrial Battery Recycling sector, cooperation among government agencies, battery producers, and research facilities is encouraging invention. Materials, manufacturing methods, and reasonably priced production are all benefiting from joint research projects.

Sustainability and Environmental Concerns

Adoption of dual carbon batteries is strongly influenced by environmental sustainability. Comprising mostly of carbon materials, these batteries are seen as more environmentally benign than conventional lithium-ion batteries, which depend on rare and maybe dangerous re Battery Types. Although dual carbon batteries are finding use in other industries as well, electric vehicles are a common Battery Type. These cover consumer electronics, industrial battery types, renewable energy storage, and even airplanes, where dependability and safety are very important. As sustainability takes center stage, reusing and recycling battery components are starting trends. By use of effective recycling techniques for dual carbon batteries, waste may be minimized, manufacturing costs can be lowered, and environmentalues can be addressed.

Government Support and Regulations

Governments worldwide are recognizing the potential of dual carbon batteries in achieving clean energy goals. Supportive policies, incentives, and regulations are encouraging research, development, and adoption of this technology. Recent disruptions in global supply chains have demonstrated the value of diversification and resilience. Dual carbon batteries, with their reduced reliance on critical materials, offer a more stable supply chain, making them attractive to industries and governments.

Segmental Insights

Battery Type Insights

Lithium-ion batteries are the fastest-growing segment due to the increasing demand for them in electric vehicles and renewable energy storage systems. Lead-acid batteries are the most common type of battery used in the world. They are used in a wide variety of applications, including automotive, industrial, and portable electronics. Lead-acid batteries are also the most recycled type of battery, due to the high demand for lead in the manufacturing of new batteries. Lithium-ion batteries are the fastest-growing type of battery in the world. They are used in various applications, including electric vehicles, renewable energy storage systems, and portable electronics. Lithium-ion batteries are pricier than lead-acid batteries, but they offer longer lifespans and better performance. Lithium-ion batteries are also recycled in significant quantities, but the recycling process is more complex and expensive than the recycling of lead-acid batteries. The industrial battery recycling market is also segmented by chemistry. The main chemicals recycled from batteries are lead, nickel, cobalt, lithium, and other metals. Lead is the most recycled battery metal due to the high demand for it in the manufacturing of new batteries. Due to their high value, we also recycle nickel and cobalt in significant quantities.

Chemistry Insights

The market is segmented into lead, nickel, cobalt, lithium, and other metals. Lead is the most recycled battery metal due to the high demand for lead in the manufacturing of new batteries. Nickel and cobalt are also recycled in significant quantities due to their high value.

Regional Insights

The Asia pacific region has established itself as the leader in the Global Industrial Battery Recycling Market with a significant revenue share in 2022

Download Free Sample Ask for Discount Request Customization

Recent Developments

- In April 2021, researchers at IIT Hyderabad, India, developed a 5V Industrial Battery Recycling utilizing self-standing carbon fiber mats as both electrodes (cathode and anode). This new model sets aside the requirement for toxic, costly, and heavy transitional metals.

Key Market Players

- Umicore

- Retriev Technologies

- American Battery Technology Company (ABTC)

- Li-Cycle

- Aqua Metals

- Battery Solutions

- Recupyl

- Gopher ReBattery Type

- Glencore Recycling

- Retech Recycling Technology AB.

|

By Chemistry |

By Battery Type |

By Region |

|

· Lead · Nickel · Cobalt · Lithium · Other Metals |

· Lead-Acid Batteries · Nickel-Cadmium Batteries · Nickel Metal Hydride Batteries · Lithium-Ion Batteries |

· North America · Europe · Asia Pacific · South America · Middle East & Africa |

Related Reports

- Industrial Electric Boiler Market - By Voltage Rating (Low Voltage, Medium Voltage), By Capacity (< 10 MMBtu/hr, 10-50 M...

- Biomass Boiler Market - By Feedstock (Woody Biomass, Agricultural Waste, Industrial Waste, Urban Residue), By Product (S...

- Asia Pacific Electric Boiler Market Size - By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 - 100 MMBtu/hr, > 100 ...

- North America & Europe Electric Boiler Market Size - By Voltage Rating (Low Voltage, Medium Voltage), By Application (Re...

- North America Residential Boiler Market Size - By Fuel (Natural Gas, Oil, Electric), By Technology (Condensing {Natural ...

- U.S. Commercial Boiler Market – By Product (Hot Water, Steam), Application (Offices, Healthcare Facilities, Educationa...

Table of Content

- 1. Executive Summary

- 1.1. Key Findings

- 1.2. Market Overview

- 1.3. Future Outlook

- 2. Introduction to the Industrial Battery Recycling Market

- 2.1. What is Industrial Battery Recycling?

- 2.2. Types of Industrial Batteries Recycled

- 2.3. Importance of Recycling Industrial Batteries

- 2.4. Scope of the Report

- 3. Market Overview

- 3.1. Current Market Size and Valuation (2025)

- 3.2. Market Dynamics

- 3.2.1. Drivers of Market Growth

- 3.2.1.1. Increasing Waste from Industrial Batteries

- 3.2.1.2. Growing Environmental Regulations

- 3.2.1.3. Rising Value of Recovered Materials

- 3.2.1.4. Focus on Circular Economy

- 3.2.2. Challenges and Restraints

- 3.2.2.1. Complexity of Battery Chemistries

- 3.2.2.2. Logistical Challenges in Collection and Transportation

- 3.2.2.3. Economic Viability of Recycling Processes

- 3.2.1. Drivers of Market Growth

- 4. Market Segmentation

- 4.1. By Battery Type

- 4.1.1. Lead-Acid

- 4.1.2. Lithium-Ion

- 4.1.3. Nickel-Cadmium

- 4.1.4. Other Industrial Battery Types

- 4.2. By Recycling Process

- 4.2.1. Pyrometallurgy

- 4.2.2. Hydrometallurgy

- 4.2.3. Other Processes

- 4.3. By Recovered Material

- 4.3.1. Lead

- 4.3.2. Lithium

- 4.3.3. Cobalt

- 4.3.4. Nickel

- 4.3.5. Other Materials

- 4.1. By Battery Type

- 5. Regional Analysis

- 5.1. North America

- 5.2. Europe

- 5.3. Asia Pacific

- 5.4. Rest of the World

- 6. Competitive Landscape

- 6.1. Market Share Analysis of Key Players

- 6.2. Profiles of Major Recycling Companies

- 6.3. Recent Developments and Collaborations

- 7. Technological Trends and Innovations

- 7.1. Advancements in Recycling Technologies

- 7.2. Focus on Higher Material Recovery Rates

- 7.3. Development of More Sustainable Recycling Methods

- 8. Future Outlook and Projections (up to 2029)

- 8.1. Forecasted Market Size and CAGR

- 8.2. Emerging Opportunities in Industrial Battery Recycling

- 8.3. Impact of New Regulations and Technologies

- 9. Conclusion

To get a detailed Table of contents/Table of figures/Methodology Please contact our salesperson at (chris@marketinsightsresearch.com)

To get a detailed Table of contents/Table of figures/Methodology Please contact our salesperson at (chris@marketinsightsresearch.com)

FAQ'S

For a single, multi and corporate client license, the report will be available in PDF format. Sample report would be given you in excel format. For more questions please contact:

Within 24 to 48 hrs.

You can contact Sales team (sales@marketinsightsresearch.com) and they will direct you on email

You can order a report by selecting payment methods, which is bank wire or online payment through any Debit/Credit card, Razor pay or PayPal.

Discounts are available.

Hard Copy