Cryogenic Pump Market

Cryogenic Pump Market – Global Industry Size, Share, Trends, Opportunity, and Forecast Segmented By Type (Positive Displacement Pumps, Kinetic Pumps, and Entrapment Pumps), By Application (Nitrogen, Hydrogen, Helium, Liquefied Natural Gas(LNG) , and Others), By End-use Industry (Healthcare Industry, Energy & Power Generation Industry, Electricals & Electronics Industry, Others), By Region, Competition 2024-2028

Published Date: May - 2025 | Publisher: MIR | No of Pages: 320 | Industry: Power | Format: Report available in PDF / Excel Format

View Details Buy Now 2890 Download Free Sample Ask for Discount Request Customization| Forecast Period | 2024-2028 |

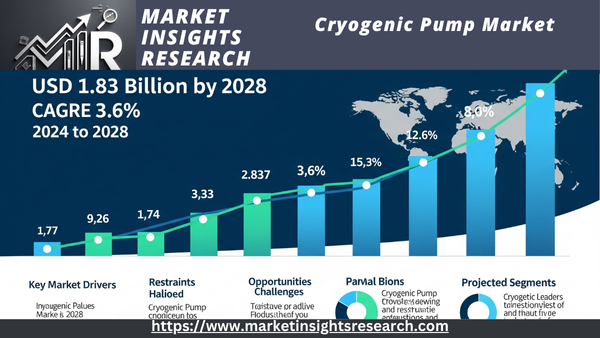

| Market Size (2022) | USD 1.83 Billion |

| CAGR (2023-2028) | 3.6% |

| Fastest Growing Segment | Positive displacement |

| Largest Market | Asia Pacific |

Market Overview

The global cryogenic pump market is expected to grow at a consistent compound annual growth rate (CAGR) of 3.6% from 2024 to 2028, reaching a value of USD 1.83 billion. This expansion is a result of growing industry demand for effective, high-performing cryogenic systems.

Download Free Sample Ask for Discount Request Customization

Key Market Drivers

Technological Advancements

The ongoing technological developments in pump design, materials, and manufacturing techniques are among the main factors driving the worldwide cryogenic pump market. Pump performance, dependability, and efficiency have all increased as a result of these developments. The following significant technological developments are fueling the market's expansionMagnetic bearing-equipped cryogenic pumps have become more and more popular because of their contactless operation, which lowers wear and friction. Higher rotational speeds and smoother operation are made possible by magnetic bearings, which improve pump performance and extend its lifespan. Through the analysis of fluid flow, temperature gradients, and pressure drops, manufacturers have been able to optimize pump designs through the use of Computational Fluid Dynamics (CFD) modeling tools. As a result, cryogenic pumps have become more dependable and efficient. Superconducting materials have decreased heat generation and increased energy efficiency in cryogenic pump components. Pumps can function at lower temperatures thanks to superconducting materials, which improves their efficiency even further. The development of smaller, more compact pumps appropriate for a greater range of applications has been made possible by the miniaturization of cryogenic pump components. As a result, the market has reached more sectors that need space-efficient solutions.

Increasing Demand for Liquefied Gases

Demand for liquefied gases, including LNG, liquid nitrogen, and liquid oxygen, has been rising consistently on a global scale. Numerous variables, including as the energy industry, medicinal and healthcare applications, and industrial applications, are driving this expansion. In many industrial processes, such as the freezing of food, the processing of metal, and the production of electronics, cryogenic pumps are essential. The requirement for cryogenic pumps has increased as a result of the growing demand for these applications. 2.2. Medical and HealthcareCryogenic pumps are essential for laboratory research, cryopreservation, and medical applications such as MRI equipment. The need for these applications will increase as the healthcare industry develops further. For the production and transportation of LNG, a cleaner and more effective fuel source, the energy industry mostly depends on cryogenic pumps. The need for cryogenic pumps rises in tandem with the global expansion of LNG infrastructure.

Download Free Sample Ask for Discount Request Customization

Expanding Applications

The proliferation of applications across several sectors is driving growth in the worldwide cryogenic pump market. Cryogenic pumps are finding new applications in developing fields outside of the conventional ones of gas liquefaction and industrial operations. For spacecraft and rocket engines to handle propellants like liquid hydrogen and liquid oxygen, cryogenic pumps are necessary. The need for sophisticated cryogenic pumping technology is being driven by the increased interest in satellite deployment and space exploration. Clean energy sources like hydrogen, which may be created using renewable energy, are being investigated for storage and transportation using cryogenic technology. In these applications, cryogenic pumps are essential to the transition to a more sustainable energy future. The limits of cryogenic science and technology are constantly being pushed by research institutes and labs. For studies involving superconductivity, quantum computing, and extremely low temperatures, cryogenic pumps are essential instruments. In conclusion, a mix of growing applications across many sectors, rising demand for liquefied gases, and technical developments is propelling the worldwide cryogenic pump market's notable expansion. Cryogenic pumps are getting more effective, dependable, and adaptable as technology develops. Furthermore, the market for cryogenic pumps is expected to rise in the future due to the rising demand for liquefied gases worldwide and the use of cryogenic technology in developing industries.

Key Market Challenges

The growing need for liquefied gases, technical developments, and the growing number of applications in different industries have all contributed to the amazing rise of the global cryogenic pump market. But in addition to these prospects, the market is confronted with a number of important problems that call for consideration and calculated answers. This article examines the main issues facing the worldwide cryogenic pump market, along with potential solutions.

High Initial Investment Costs

The high upfront costs of purchasing and setting up cryogenic pump systems are one of the main issues confronting the worldwide cryogenic pump market. These expenses cover the acquisition of specialist machinery, setup, and modifications to the infrastructure required to support cryogenic operations.

Industry participants can investigate cooperative finance solutions as a solution to this problem. To distribute the initial investment burden, this entails collaborations between pump producers, end users, and financial institutions. Shared infrastructure initiatives, equipment finance, and lease-to-own contracts can all assist in lowering costs and increasing accessibility to cryogenic pump technology.

The handling of extremely low-temperature materials during cryogenic operations presents inherent safety hazards. It is crucial to guarantee the security of the environment, workers, and equipment. Additionally, cryogenic pump systems are subject to stringent regulatory requirements, which can differ depending on the location.

Comprehensive Training and Compliance

Strong operator training programs and frequent safety audits are necessary to address safety risks. To create thorough rules and standards, pump makers should work with trade associations and government agencies. Safety hazards can be reduced and regulatory compliance can be guaranteed by proactive compliance and adherence to best practices. Because cryogenic pumps work in harsh environments, maintaining them can be difficult and expensive. Cryogenic pumps are prone to wear and tear, and malfunctions can result in substantial production losses and downtime. This problem can be solved by putting predictive maintenance techniques into practice. Cryogenic pump systems can be equipped with sensors and monitoring systems to gather data on pump performance in real time. Operators can minimize unplanned downtime and expensive repairs by using this data to forecast when maintenance is required.

Because they must maintain the extremely low temperatures necessary for their operation, cryogenic pump systems are energy-intensive and demand significant quantities of electricity. In addition to increasing operating expenses, this excessive energy usage also poses environmental issues.

Download Free Sample Ask for Discount Request Customization

Energy-Efficient Designs and Renewable Energy Integration

It is essential to create cryogenic pump designs that use less energy. In order to improve pump components and lower energy consumption, manufacturers can spend money on research and development. Furthermore, the environmental impact can be lessened by incorporating renewable energy sources into cryogenic operations, such as employing renewable power for liquefaction procedures.

Key Market Trends

Advances in technology, growing applications across several industries, and rising demand for liquefied gases have all contributed to the expansion of the global cryogenic pump market. Examining the new trends influencing the market's future is crucial to comprehending its dynamics on a deeper level. The main trends impacting the worldwide cryogenic pump industry are examined in this study along with their ramifications.

Growing Demand for Renewable Energy

The growing need for hydrogen and other renewable energy sources is one of the major trends in the cryogenic pump market. When transported and stored as a cryogenic liquid, hydrogen provides an extremely effective and energy-dense solution. The global movement toward sustainable energy and initiatives to lower greenhouse gas emissions are the main drivers of this trend.

Strong cryogenic pump systems for hydrogen liquefaction, storage, and distribution are required due to the rising demand for hydrogen as an energy carrier. In order to support the developing hydrogen economy, manufacturers are investing in cutting-edge cryogenic pumps and infrastructure. The desire for cleaner-burning fuels around the world is driving the liquefied natural gas (LNG) industry's continued rapid expansion. The liquefaction and transportation of LNG depend heavily on cryogenic pumps, which makes this industry a major driver of the cryogenic pump market. Investments are flooding into the construction of LNG terminals, liquefaction facilities, and transportation networks in order to fulfill the growing demand for LNG. Manufacturers of cryogenic pumps are coming up with new ways to serve this growing business by creating high-capacity, energy-efficient pumps.

Space Exploration and Aerospace Applications

For the management of liquid hydrogen and liquid oxygen propellants, the aerospace and space exploration industries are depending more and more on cryogenic pump technology. The need for sophisticated cryogenic pumping solutions has increased due to the growing interest in interplanetary missions, satellite deployment, and space exploration. Manufacturers of cryogenic pumps are creating specialized space-grade pumps that can endure the harsh conditions of space flight in order to satisfy the particular needs of space applications. These developments are essential to the advancement of space exploration.

Carbon capture and utilization (CCU) technologies, especially in high-carbon industries, are utilizing cryogenic technology. Carbon dioxide can be captured and used for a number of purposes, including the manufacturing of chemicals and carbon-neutral fuels, using cryogenic separation processes. Innovation in cryogenic pumps and equipment is being propelled by the use of cryogenic CCU technologies. These technologies are growing more economical and energy-efficient, which helps the market expand while solving environmental issues. Applications for cryogenic pumps are expanding beyond conventional gas liquefaction procedures. Cryogenic solutions are being investigated by industries like food processing, biotechnology, and pharmaceuticals for their particular temperature-sensitive procedures.

Segmental Insights

Type Insights

Centrifugal pumps now have the largest market share because of their technical benefits, which include fewer moving parts, lower maintenance costs, and longer lifespans. By transforming rotational energy from an external motor or engine into energy that moves the fluid, a centrifugal pump moves fluid. During pump priming, the centrifugal pump can only run on a two-phase (gas-liquid) fluid. The same output levels as a positive displacement pump are produced by their straightforward design. It can be formed of a variety of materials, such as plastic, cast iron, and stainless steel, and has a large capacity and relatively low head. It can also be customized to meet specific needs. Because of these benefits, centrifugal pumps are being used more and more in the steel, food and beverage, metal and mining, and oil and gas industries. By holding onto a fixed volume of fluid and forcing it through the discharge pipe, a positive displacement cryogenic pump moves fluid. The cryogenic liquid is deliberately moved from one location to another using these pumps. They are favored in any application requiring precise dosing or high-pressure output and are utilized to pump fluids with a high viscosity.

End-Use Industry Insights

Because these pumps are fully utilized in the gas-to-liquid operations throughout the oil and gas sector, the oil and gas category, which includes pumps for oil and gas activities involving cryogenic liquefied natural gas, holds the largest market share. Large amounts of cryogenic gases, including nitrogen, are utilized in the metallurgy sector to produce metals. Since nitrogen is utilized as a high-pressure gas for laser cutting steel and other metals, it is thought to be the most used cryogenic gas in the industry. Transporting and storing cryogenic liquid from one place to another is the main function of the marine industry. Therefore, the need for cryogenic liquid storage tanks and vessels in the maritime sector is a result of the increasing demand for LNG from different regional areas.

Regional Insights

The Asia Pacific region has established itself as the leader in the Global Cryogenic Pump Market with a significant revenue share in 2022

North America also dominates the cryogenic pump market. The demand will be driven by rising industrial infrastructure sectors and rising investment in the oil and gas sector. Additionally, the region's prospective market for LNG exports is the United States and Canada, as the necessity for LNG-based power plants is fueled by the region's declining coal reserves. The need for the market is driven by Europe's growing emphasis on creating a clean energy source, which raises demand for LNG and reduces the volume of cargoes being reloaded at European import terminals. Due to new investment schemes and innovations, governments, and businesses performing investment assignments on the construction, development, and transformation of LNG regasification and LNG production factories, Latin America offers prospective growth opportunities for LNG demand. Due to its increased involvement in natural gas production and transactions, the Middle East and Africa are the most prominent regions involved in the oil and gas industry. Due to rising power consumption, seasonal instability, and rapid industrial growth, the Gulf countries in the Middle East are experiencing the fastest growth in energy demand.

Download Free Sample Ask for Discount Request Customization

Recent Developments

- January 2022 – The cryogenic solution specialist Cryostar announced that it had received NeoVP vertical pumps for the Chinese market. These pumps will be installed in air separation units. NeoVP vertical pumps are designed for easy installation and maintenance, and they also possess hydraulic efficiency, reducing the unit’s carbon footprint and energy costs.

- April 2021 - Nikkiso Co., Ltd. announced a new facility adjacent to their primary production test site to increase the efficiency and capability of producing cryogenic submerged electric motor pumps, especially for the LNG market. This facility is also expected to facilitate customer remote-site witness testing.

Key Market Players

- Atlas Copco AB

- Ebara Corporation

- Cryostar

- Fives

- Flowserve Corporation

- Gemmecotti Srl,

- Nikkiso Co., Ltd.

- Ruhrpumpen

- SHI Cryogenics Group

- Trillium Flow Technologies

|

By Type |

By Application |

By End-Use Industry |

By Region |

|

|

|

|

Related Reports

- Commercial Boiler Market - By Fuel (Natural Gas, Oil, Coal, Electric), By Capacity, By Technology (Condensing, Non-Conde...

- Steam Boiler Market - By Capacity, By Fuel (Natural Gas, Oil, Coal), By Technology (Condensing, Non-Condensing), By Appl...

- Industrial Electric Boiler Market - By Voltage Rating (Low Voltage, Medium Voltage), By Capacity (< 10 MMBtu/hr, 10-50 M...

- Biomass Boiler Market - By Feedstock (Woody Biomass, Agricultural Waste, Industrial Waste, Urban Residue), By Product (S...

- Asia Pacific Electric Boiler Market Size - By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 - 100 MMBtu/hr, > 100 ...

- North America & Europe Electric Boiler Market Size - By Voltage Rating (Low Voltage, Medium Voltage), By Application (Re...

Table of Content

-

Executive Summary

-

1.1 Market Overview

-

1.2 Key Trends and Insights

-

1.3 Strategic Recommendations

-

-

Introduction

-

2.1 Scope of the Report

-

2.2 Research Methodology

-

2.3 Definitions and Assumptions

-

-

Market Overview

-

3.1 What Are Cryogenic Pumps?

-

3.2 Functionality and Working Principles

-

3.3 Role in Industrial Gas Handling and LNG Systems

-

3.4 Value Chain and Industry Ecosystem

-

-

Market Dynamics

-

4.1 Drivers

-

4.1.1 Growth in LNG Infrastructure and Gas-Based Economy

-

4.1.2 Rising Demand for Industrial Gases in Manufacturing and Healthcare

-

4.1.3 Advancements in Space and Aerospace Propellant Systems

-

-

4.2 Restraints

-

4.2.1 High Operational and Maintenance Costs

-

4.2.2 Volatility in Gas Prices and Supply Chain Disruptions

-

-

4.3 Opportunities

-

4.3.1 Hydrogen Economy and Cryogenic Hydrogen Applications

-

4.3.2 Emerging Demand in Semiconductor and Cryotherapy Markets

-

-

4.4 Challenges

-

4.5 Porter’s Five Forces Analysis

-

-

Technology Landscape

-

5.1 Centrifugal Cryogenic Pumps

-

5.2 Positive Displacement and Piston-Type Pumps

-

5.3 Submerged vs. Non-Submerged Pumps

-

5.4 Key Materials and Insulation Techniques

-

5.5 Pump Performance Metrics and Safety Standards

-

-

Market Segmentation

-

6.1 By Type

-

6.1.1 Centrifugal

-

6.1.2 Positive Displacement

-

-

6.2 By Cryogenic Liquid

-

6.2.1 Liquid Nitrogen

-

6.2.2 Liquid Oxygen

-

6.2.3 Liquid Hydrogen

-

6.2.4 Liquid Argon

-

6.2.5 LNG

-

6.2.6 Others

-

-

6.3 By Application

-

6.3.1 Energy & Power

-

6.3.2 Chemical & Petrochemical

-

6.3.3 Metallurgy

-

6.3.4 Healthcare & Biomedical

-

6.3.5 Aerospace & Defense

-

6.3.6 Electronics

-

-

-

Regional Analysis

-

7.1 North America

-

7.2 Europe

-

7.3 Asia-Pacific

-

7.4 Latin America

-

7.5 Middle East & Africa

-

-

Market Size and Forecast (2020–2030)

-

8.1 Global Revenue Forecast by Region and Segment

-

8.2 Capacity Installation and Volume Outlook

-

8.3 LNG and Hydrogen Market Correlation

-

-

Competitive Landscape

-

9.1 Market Share of Leading Manufacturers

-

9.2 Company Profiles

-

9.2.1 Cryostar

-

9.2.2 Nikkiso Co., Ltd.

-

9.2.3 Weir Group

-

9.2.4 Ebara Corporation

-

9.2.5 Fives Group

-

9.2.6 Others

-

-

9.3 Technological Developments and Strategic Collaborations

-

-

Regulatory and Industry Standards

-

10.1 ASME, ISO, API Standards for Cryogenic Systems

-

10.2 Safety Guidelines for Handling Liquefied Gases

-

10.3 Environmental and Energy Efficiency Regulations

-

-

Innovation and Future Outlook

-

11.1 Role in Hydrogen Refueling Infrastructure

-

11.2 Smart Monitoring and Predictive Maintenance

-

11.3 Decarbonization Trends and Green Industrial Gases

-

-

Conclusion and Strategic Outlook

-

Appendices

-

13.1 Glossary

-

13.2 Research Methodology

-

13.3 References and Sources

-

To get a detailed Table of content/ Table of Figures/ Methodology Please contact our sales person at ( chris@marketinsightsresearch.com )

FAQ'S

For a single, multi and corporate client license, the report will be available in PDF format. Sample report would be given you in excel format. For more questions please contact:

Within 24 to 48 hrs.

You can contact Sales team (sales@marketinsightsresearch.com) and they will direct you on email

You can order a report by selecting payment methods, which is bank wire or online payment through any Debit/Credit card, Razor pay or PayPal.

Discounts are available.

Hard Copy