Parallel Shaft Geared Motors Market

Parallel Shaft Geared Motors Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, 2018-2028 Segmented By Shaft Type (Solid Shaft, Splined Hollow Shaft, and Hollow Shaft with Shrink Disc), By Stage (2-stage, 3-stage, and Other Stages), By Application (Energy Industry, Food and Beverages, Automotive & Transportation, Others), By Region, By Competition

Published Date: May - 2025 | Publisher: MIR | No of Pages: 320 | Industry: Power | Format: Report available in PDF / Excel Format

View Details Buy Now 2890 Download Free Sample Ask for Discount Request Customization| Forecast Period | 2024-2028 |

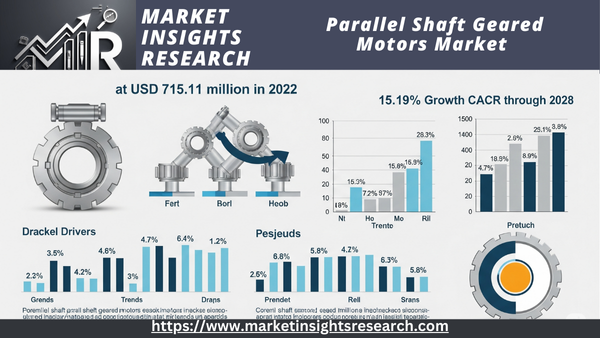

| Market Size (2022) | USD 715.11 million |

| CAGR (2023-2028) | 15.19% |

| Fastest Growing Segment | Automotive & Transportation |

| Largest Market | North America |

Market Overview

With a 2022 valuation of USD 715.11 million, the global parallel shaft geared motors market is expected to increase at a strong rate during the forecast period, with a compound annual growth rate (CAGR) of 15.19 percent through 2028. The manufacturing, marketing, and application of geared motors with parallel shafts are the main objectives of the Parallel Shaft Geared Motors market, a niche business within the larger industrial machinery industry.

Download Free Sample Ask for Discount Request Customization

When precise and controlled mechanical power transfer is needed in a variety of industrial applications, these motors are essential. Two parallel shafts coupled by gears of varying sizes to accomplish particular speed reduction or torque multiplication goals define the distinctive architecture of parallel shaft geared motors. Because of this arrangement, they can be used in a variety of settings, including robotics, automobile manufacturing, conveyor systems, material handling devices, and industrial automation. This market's key characteristics include a wide variety of product offerings, such as worm, bevel, and helical gears, each of which is designed to satisfy particular industrial needs. Regulations pertaining to energy efficiency, technical developments, and the growing need for automation and sustainability across a range of industries all have an impact on the industry. In order to meet the changing demands of industries throughout the world, manufacturers and suppliers in the parallel shaft geared motors market are always coming up with new ways to improve product performance, energy efficiency, and flexibility.

Key Market Drivers

Industrial Automation and Robotics

The global market for parallel shaft geared motors is significantly influenced by the exponential increase in industrial automation and robotics in recent years. The need for high-performance geared motors, particularly parallel shaft geared motors, has increased as a result of industries all over the world embracing automation more and more to increase productivity and lower operating expenses. Geared motors provide the exact motion control needed for automated machinery such as conveyor systems, industrial robots, and others. Applications requiring efficient torque transmission and limited space are best suited for parallel shaft geared motors. These motors are essential to automated machinery because they provide smooth, dependable, and regulated movement. The need for parallel shaft geared motors has increased due to the growing acceptance of Industry 4.0, which is defined by the use of IoT, AI, and data analytics into production processes. For smart factories and sophisticated automation systems, these motors provide exact synchronization and control. As a result, it is anticipated that the global market for parallel shaft geared motors will keep growing in tandem with the growing use of automation and robotics in sectors like electronics and the automotive industry.

Energy Efficiency and Environmental Sustainability

Stringent energy efficiency standards and sustainability concerns have emerged as major factors propelling the global market for parallel shaft geared motors. The selection of motor technology becomes crucial as industries work to lower their energy and carbon impact. Due to their great power transfer efficiency, parallel shaft geared motors have become more popular among eco-aware businesses. These motors have remarkable efficiency ratings, frequently above 90%. Because of its great efficiency, less energy is used and less greenhouse gas emissions are released, which supports international efforts to mitigate climate change. In order to lower their energy costs and environmental effect, manufacturing and other industries that rely significantly on electric motors are progressively switching to parallel shaft geared motors from antiquated, inefficient motors. Industrial facilities are also being encouraged to use energy-efficient technologies, such as parallel shaft geared motors, by the introduction of energy efficiency regulations and incentives by numerous governments across the globe. As businesses strive to meet sustainability requirements and take advantage of the financial advantages of energy-efficient motors, these regulations are anticipated to further accelerate the market's growth.

Download Free Sample Ask for Discount Request Customization

Increasing Demand in Material Handling

One of the key factors propelling the global market for parallel shaft geared motors is the material handling sector. The movement, management, and safeguarding of materials in production and distribution facilities are all included in material handling. Geared motors are essential to the smooth and accurate movement of automated storage and retrieval systems, elevators, and conveyor systems that are widely used in this sector. Because of its small size and high torque capacity, parallel shaft geared motors are particularly well-suited for material handling applications. They guarantee the safe movement of products throughout industrial facilities, distribution hubs, and warehouses. Parallel shaft geared motors are becoming more and more necessary as e-commerce continues to grow and the necessity for effective material handling systems has increased dramatically. E-commerce is not the only industry growing; the food and beverage, pharmaceutical, and automotive sectors are also expanding, which raises the need for material handling equipment. As a result, the market for parallel shaft geared motors is anticipated to grow steadily as it integrates into contemporary material handling solutions.

Automotive Industry Advancements

The global market for parallel shaft geared motors is mostly driven by the automobile sector. Compact, high-torque motors are becoming more and more necessary as automakers continue to innovate and build hybrid and electric cars (EVs). These motors will power a variety of components, including power windows, sunroofs, and windshield wipers. Because they provide the torque and exact control needed for these auxiliary systems, parallel shaft geared motors are widely used in the automotive industry. Furthermore, the demand for geared motors for power management and transmission has increased as a result of the shift to electric powertrains in automobiles, particularly hybrid and electric cars. For features like automatic transmission and regenerative braking, geared motors are very important in EVs. The market for parallel shaft geared motors is expected to expand rapidly in concert with the automobile industry's ongoing transition towards automation and electrification.

Expanding Construction and Infrastructure Projects

Another significant factor propelling the global market for parallel shaft geared motors is the infrastructure and building industry. In these industries, geared motors are essential for a variety of applications, such as concrete mixers, conveyor belts, cranes, and hoists. Urbanization, population growth, and the need for modern infrastructure have all contributed to an increase in the demand for building and infrastructure projects. As a result, there is a greater need than ever for geared motors to run heavy machinery and equipment. Parallel shaft geared motors' robustness, high torque capacity, and small size make them ideal for construction applications. They guarantee the dependable and effective operation of machinery used to construct highways, skyscrapers, bridges, and other vital infrastructure.

Technological Advancements in Motor Design

Technological and design developments in motors are driving the global market for parallel shaft geared motors. In order to satisfy the changing demands of several industries, motor makers are always inventing to provide motors that are more dependable, efficient, and compact. High-strength alloys and sophisticated composites are examples of contemporary materials being used to improve the longevity and performance of geared motors. Furthermore, parallel shaft geared motors are becoming more suitable for Industry 4.0 and Internet of Things applications with the incorporation of intelligent elements like sensors and connectivity choices. In addition to increasing geared motor performance, these technological developments are also prolonging their lifespan and lowering maintenance needs. For long-term cost savings and operational efficiency, industries are therefore more likely to invest in parallel shaft geared motors.

In conclusion, a number of factors are propelling the global market for parallel shaft geared motors, including the growing use of robotics and industrial automation, sustainability concerns, the expansion of the material handling sector, developments in the automotive industry, growing infrastructure and construction projects, and continuous technological advancements. All of these factors work together to support the market's growth as it continues to be essential to the operation of several industrial applications around the globe.

Download Free Sample Ask for Discount Request Customization

Government Policies are Likely to Propel the Market

Energy Efficiency Standards and Incentives

One of the main factors propelling the global market for parallel shaft geared motors is energy efficiency rules and incentives. Governments everywhere understand how critical it is to cut industry energy use in order to slow down climate change and advance sustainable development. In order to accomplish these objectives, they have put in place a number of laws designed to promote the use of energy-efficient devices, such as geared motors. Setting energy efficiency guidelines for electric motors, especially parallel shaft geared motors, is one popular practice. Motors must fulfill these standards' minimum efficiency requirements in order to be offered for sale. In order to maintain their competitiveness and legal compliance, manufacturers must make sure that their products fulfill or surpass these requirements. Businesses and industries who invest in energy-efficient machinery, such as parallel shaft geared motors, can also receive financial incentives from the government in the form of tax credits or refunds. These subsidies encourage businesses to put sustainability at the forefront of their operations and assist defray the upfront costs associated with buying energy-efficient motors. These regulations encourage the use of parallel shaft geared motors that use less energy, which lowers greenhouse gas emissions and lowers operating costs for companies.

Trade Tariffs and Import Restrictions

Government-imposed import restrictions and trade tariffs can have a big effect on the global market for parallel shaft geared motors. These regulations have the potential to either promote homegrown production or impede global geared motor trade. To safeguard domestic producers, governments may impose taxes on the import of parallel shaft geared motors. Local producers get a competitive edge as a result of these levies, which raise the cost of imported motors. Increased domestic manufacturing, employment creation, and the expansion of the domestic auto sector are the goals of this program. On the other hand, governments can lower tariffs and enact free trade agreements to promote the usage and importation of superior parallel shaft geared motors. Governments may guarantee that companies have access to the newest products and technology at competitive rates by promoting the movement of goods internationally. Individual nations' and regions' trade policies determine how import restrictions and trade tariffs affect the global market for parallel shaft geared motors. Market distributors and manufacturers need to keep up with trade laws and modify their tactics properly.

Environmental Regulations and Emissions Standards

The global market for parallel shaft geared motors is significantly shaped by environmental laws and emissions limits. Governments are paying more attention to regulating emissions from industrial activities and lowering environmental pollution. Many industrial applications depend on geared motors, and regulations are closely monitoring their emissions and energy usage. Environmental laws and emissions limits may be enforced by governments, which may have an impact on the kinds of motors that are permitted in particular applications. For instance, parallel shaft geared motors with minimal emissions and excellent energy efficiency could be required in companies or locations that are sensitive to the environment. In order to encourage accountability and transparency, governments may also mandate that businesses submit data on their energy use and emissions. In order to comply with regulations and lessen their environmental impact, industries may be compelled by this knowledge to implement energy-efficient parallel shaft geared motors. Furthermore, companies that voluntarily implement eco-friendly technologies, such as energy-efficient motors, may be eligible for government incentives, such as tax cuts or grants. These regulations incentivize businesses to purchase parallel shaft geared motors that support environmental objectives.

Safety and Quality Standards

To guarantee the dependability and efficiency of parallel shaft geared motors, government regulations pertaining to safety and quality requirements are crucial. These guidelines are designed to shield industries, workers, and customers from mishaps, defective machinery, and inferior goods. Governments frequently create and implement safety regulations that motors must adhere to in order to be utilized in particular applications. For instance, in order to prevent explosions or other dangerous situations, motors used in hazardous locations must comply with stringent safety rules. These guidelines guarantee that safety is taken into consideration throughout the design and manufacturing of parallel shaft geared motors. Conversely, quality standards concentrate on the general functionality and longevity of motors. To prove that their production methods satisfy strict quality requirements, governments may mandate that manufacturers obtain certifications like ISO 9001. This guarantees consumers that the motors they buy are dependable and fit their requirements. Businesses that depend on parallel shaft geared motors are reassured by government regulations pertaining to safety and quality standards. Additionally, they aid in keeping dangerous or inferior motors off the market, protecting industrial operations' efficiency and safety.

Research and Development Grants

The global market for parallel shaft geared motors can be significantly impacted by government policies that promote research and development (R&D) funds. Governments use R&D funding as incentives to entice organizations and companies to engage in cutting-edge procedures and technologies, such as the creation of sophisticated geared motors. These funds can help motor makers develop parallel shaft geared motors that are more technologically sophisticated, compact, and efficient. Governments encourage industry innovation by funding research and development initiatives. R&D is frequently given top priority by governments in fields like sustainability, energy efficiency, and industrial competitiveness that support national objectives. Since parallel shaft geared motors are essential to achieving these goals, they qualify for R&D funding. Furthermore, R&D funds can encourage cooperation between universities, research centers, and manufacturers, resulting in the development of innovative motor technology. The industry may advance and take the lead in global competitiveness with this cooperative strategy.

Export Promotion and Trade Agreements

The global market for parallel shaft geared motors is significantly shaped by international trade agreements and government policies that encourage exports. These regulations seek to increase domestic producers' global visibility and ease the export of their goods, especially geared motors. Governments frequently set up export promotion organizations and provide financial incentives to help companies grow internationally. These incentives can include grants, subsidies, and trade missions to foreign markets, helping manufacturers connect with potential buyers and partners. Additionally, trade agreements signed between nations or regions can lower tariffs and trade obstacles, facilitating access to global markets for manufacturers of parallel shaft geared motors. These agreements encourage fair trade and give companies the chance to compete globally. Government initiatives that place a high priority on international trade agreements and export promotion can significantly affect the expansion and competitiveness of the worldwide market for parallel shaft geared motors. By utilizing these regulations, manufacturers may grow their clientele and stimulate global demand for their goods.

To sum up, the global market for parallel shaft geared motors is greatly impacted by government policies pertaining to energy efficiency standards, trade tariffs, environmental regulations, safety and quality standards, research and development grants, export promotion, and trade agreements. These regulations influence the competitiveness of enterprises and industries globally, stimulate innovation, and mold the dynamics of the market. For companies in the parallel shaft geared motors sector to successfully negotiate the regulatory environment, it is imperative that they remain up to date on these rules.

Key Market Challenges

Increasing Competition and Market Saturation

The growing competitiveness and market saturation are two major issues facing the worldwide parallel shaft geared motors industry. A growing number of manufacturers have entered the market as geared motors, notably parallel shaft geared motors, continue to be in high demand due to their extensive use in a variety of industries. This competition presents difficulties for both new and established firms, even while it can spur innovation and increase the quality of products.

Price CompetitionPrice competition is becoming increasingly common as more manufacturers compete for market share. In an effort to draw clients, businesses frequently lower their pricing, which can result in smaller profit margins. Because of this price-driven rivalry, manufacturers may find it difficult to maintain product quality, make investments in R&D, and provide customer assistance.

Market SaturationIn certain areas and sectors, the market for parallel shaft geared motors is approaching saturation. Many companies have already implemented geared motor solutions in established areas like automation and manufacturing. This restricts the potential for quick expansion in these industries, and in order to increase their clientele, producers must look for new markets and applications.

Product DifferentiationManufacturers must develop distinctive selling propositions for their goods in order to stand out in a crowded market. This calls for constant innovation, such as creating geared motors with cutting-edge features, enhanced durability, or better energy efficiency. However, it can take a lot of resources to develop and market unique items.

International Supply Chain RestrictionsThe COVID-19 epidemic brought attention to the weaknesses in international supply systems. Production can be disrupted and customer deliveries of geared motors delayed by interruptions in the supply of electronic chips, components, and raw materials. To ensure steady product availability, manufacturers need to manage these supply chain obstacles.

ConsolidationIn response to market pressures and competition, some manufacturers may consider mergers and acquisitions to consolidate their positions or gain access to new markets. Stronger, more varied businesses may result from this, but there may be fewer independent competitors in the market, which could limit the options available to consumers.

To address these challenges, manufacturers in the global Parallel Shaft Geared Motors market must focus on innovation, product differentiation, and strategic expansion into emerging markets. They should also prioritize maintaining high product quality and exploring opportunities for collaboration and partnerships to enhance their competitive edge.

Technological Advancements and Rapid Obsolescence

Another significant challenge facing the global Parallel Shaft Geared Motors market is the rapid pace of technological advancements and the consequent risk of product obsolescence. In today's dynamic industrial landscape, technological innovation is a double-edged sword—it drives progress but also necessitates constant adaptation and investment to stay relevant.

Shortened Product LifecyclesTechnological advancements lead to shorter product lifecycles in the geared motors industry. New, more efficient, and technologically advanced motor designs emerge regularly, rendering older models obsolete. This poses challenges for manufacturers in terms of managing inventory, supporting legacy products, and transitioning customers to newer solutions.

Compatibility IssuesThe introduction of advanced technologies in parallel shaft geared motors, such as IoT integration, smart sensors, and connectivity, may create compatibility issues with existing infrastructure and control systems. Customers often face the dilemma of choosing between upgrading their entire system or attempting to integrate new technologies with older components.

Cost of InnovationDeveloping and implementing cutting-edge technologies in geared motors requires substantial investments in research, development, and testing. Manufacturers must balance the cost of innovation with the potential return on investment. The risk of investing in technology that may not gain widespread adoption is a constant concern.

Skills GapAs technology advances, manufacturers may face a skills gap within their workforce. Employees may require training and upskilling to operate and maintain new, technologically advanced geared motors. Bridging this skills gap is essential to ensure the efficient operation of equipment.

Sustainability and Regulatory ComplianceEvolving environmental regulations and sustainability goals drive the development of energy-efficient geared motors. Manufacturers must stay abreast of changing regulatory requirements and invest in sustainable technologies to meet these demands while remaining competitive.

To address the challenges posed by technological advancements and rapid obsolescence, manufacturers in the Parallel Shaft Geared Motors market must adopt agile product development strategies. This includes investing in research and development, maintaining open lines of communication with customers to understand their evolving needs, and offering upgrade paths for existing equipment to extend its lifespan. Additionally, fostering a culture of innovation and continuous learning within the organization can help manufacturers stay ahead in the rapidly evolving landscape of geared motor technology.

Segmental Insights

Stage Insights

In 2022, the 3-stage category held the biggest market share, and it is anticipated to continue to do so throughout the forecast period. When compared to 2-stage motors, 3-stage geared motors usually have a larger reduction ratio. They are therefore appropriate for applications requiring significant force or load handling since they can produce more torque. Because of its multi-stage construction, 3-stage geared motors can provide tighter control in applications where exact control over speed and torque is essential. Because of this, they are useful in fields where accuracy is crucial, including robotics. Three-stage geared motors are appropriate for situations with limited space because they can maintain a relatively small form even though they offer higher reduction ratios. Three-stage geared motors are adaptable and can be used in a variety of settings in a variety of industries, such as automation, material handling, and manufacturing. High efficiency is a common design feature of contemporary 3-stage geared motors, which lowers energy consumption and running expenses. In industries that are concerned about energy, this can be a significant factor.

Application Insights

With the biggest market share in 2022, the Energy Industry category is expected to develop rapidly over the course of the forecast period. Power generation, transmission, and distribution are only a few of the many uses that fall under the broad purview of the energy sector. Because of their versatility, parallel shaft geared motors can be employed in a variety of different applications. They can be utilized, for instance, in wind turbine blade rotation, coal handling conveyor systems in power plants, and fluid flow management in oil and gas operations. Efficiency and dependability are highly valued in the energy sector. Precision, dependability, and the capacity to provide steady performance over long stretches of time are hallmarks of parallel shaft geared motors. They are therefore ideal for vital applications in the energy industry. Heavy weights and high torque needs are part of many energy industry processes. Because they can deliver the required torque, parallel shaft geared motors are a great option for jobs like material transportation or valve and damper control. Geared motors are essential for precise and regulated movements in a variety of automated systems, which helps to increase the overall efficiency of energy generation and distribution as the energy sector embraces more automation and smart technology. Extreme temperatures and challenging working circumstances, which are frequently encountered in the energy sector, are just two examples of the environmental conditions to which parallel shaft geared motors can be adapted. The energy sector is always looking for methods to cut energy use because sustainability and energy efficiency are becoming more and more important. High efficiency ratings for parallel shaft geared motors support these efforts and potentially lower energy expenses.

Regional Insights

North America

North America had the largest market for parallel shaft geared motors in 2022. The growth of the market in this region is driven by the presence of a large number of end-user industries, such as food and beverage, oil and gas, and automotive. The United States is the largest market for parallel shaft geared motors in North America, followed by Canada.

Europe

Europe had the second-largest market for parallel shaft geared motors in 2022. The growth of the market in this region is driven by the increasing demand for parallel shaft geared motors in the automotive and machinery industries. Germany is the largest market for parallel shaft geared motors in Europe, followed by France and Italy.

Asia Pacific

The Asia Pacific market is expected to grow at the fastest CAGR during the forecast period, driven by the increasing demand for parallel shaft geared motors in the food and beverage, oil and gas, and machinery industries. China is the largest market for parallel shaft geared motors in the Asia Pacific, followed by India and Japan.

Download Free Sample Ask for Discount Request Customization

Recent Developments

- In March 2023, Siemens announced that it would invest USD 107.89 million in its manufacturing facility in Amberg, Germany. The investment will be used to expand the production capacity of parallel shaft geared motors.

- In February 2023, SEW-Eurodrive announced that it would invest USD 53.92 million in its manufacturing facility in Wassertrüdingen, Germany. The investment will be used to expand the production capacity of parallel shaft geared motors and to develop new products.

- In January 2023, Nord announced that it would invest USD 32.35 million in its manufacturing facility in Bargteheide, Germany. The investment will be used to expand the production capacity of parallel shaft geared motors and to develop new products.

- In December 2022, Bosch Rexroth announced that it would invest USD 10 million in its manufacturing facility in Fort Wayne, Indiana. The investment will be used to expand the production capacity of parallel shaft geared motors.

- In November 2022, Emerson announced that it would invest USD 5 million in its manufacturing facility in Pune, India. The investment will be used to expand the production capacity of parallel shaft geared motors.

Key Market Players

- Siemens AG

- SEW-EURODRIVE GmbH & Co KG

- NORD Drivesystems

- Bosch Rexroth AG

- Emerson Electric Co.

- ABB Ltd

- Sumitomo Heavy Industries Ltd

- Bonfiglioli S.p.A.

- Regal Rexnord Corporation

- WEG S.A.

|

By Shaft Type |

By Stage |

By Application |

By Region |

|

|

|

Related Reports

- Asia Pacific Electric Boiler Market Size - By Capacity (≤ 10 MMBtu/hr, > 10 - 50 MMBtu/hr, > 50 - 100 MMBtu/hr, > 100 ...

- North America & Europe Electric Boiler Market Size - By Voltage Rating (Low Voltage, Medium Voltage), By Application (Re...

- North America Residential Boiler Market Size - By Fuel (Natural Gas, Oil, Electric), By Technology (Condensing {Natural ...

- U.S. Commercial Boiler Market – By Product (Hot Water, Steam), Application (Offices, Healthcare Facilities, Educationa...

- North America Commercial Boiler Market Size - By Fuel (Natural Gas, Oil, Coal, Electric), By Capacity, By Technology (Co...

- Water Tube Industrial Boiler Market Size By Capacity, By Application (Food Processing, Pulp & Paper, Chemical, Refinery,...

Table of Content

-

Executive Summary

-

1.1 Market Snapshot

-

1.2 Key Trends and Developments

-

1.3 Strategic Recommendations

-

-

Introduction

-

2.1 Report Objectives and Scope

-

2.2 Research Methodology

-

2.3 Definitions and Assumptions

-

-

Market Overview

-

3.1 What Are Parallel Shaft Geared Motors?

-

3.2 Operating Mechanism and Core Components

-

3.3 Comparison with Other Geared Motor Configurations

-

3.4 Key Applications Across Industries

-

-

Market Dynamics

-

4.1 Market Drivers

-

4.1.1 Increased Automation in Manufacturing and Logistics

-

4.1.2 Energy Efficiency and Torque Optimization in Industrial Settings

-

4.1.3 Adoption in Compact and Space-Constrained Installations

-

-

4.2 Market Restraints

-

4.2.1 High Initial Costs and Maintenance Requirements

-

4.2.2 Competition from Helical and Planetary Gear Configurations

-

-

4.3 Market Opportunities

-

4.3.1 Smart Motor Integration with IoT and Monitoring Systems

-

4.3.2 Emerging Demand in Green and Modular Machinery

-

-

4.4 Challenges

-

4.5 Porter’s Five Forces Analysis

-

-

Technology Landscape

-

5.1 Motor Types (AC, DC, Servo)

-

5.2 Gear Material Innovations (Alloy, Composite, Hardened Steel)

-

5.3 Lubrication and Thermal Management Systems

-

5.4 Enclosures and Protection Ratings (IP, Explosion Proof)

-

5.5 Smart Gear Motors and Predictive Maintenance

-

-

Market Segmentation

-

6.1 By Power Rating

-

6.1.1 Up to 5 kW

-

6.1.2 5–15 kW

-

6.1.3 Above 15 kW

-

-

6.2 By Output Torque

-

6.2.1 Low Torque

-

6.2.2 Medium Torque

-

6.2.3 High Torque

-

-

6.3 By Application

-

6.3.1 Conveyors and Material Handling

-

6.3.2 Food & Beverage Processing

-

6.3.3 Automotive Manufacturing

-

6.3.4 Water Treatment and Pumps

-

6.3.5 Packaging Machinery

-

6.3.6 Others

-

-

-

Regional Market Analysis

-

7.1 North America

-

7.2 Europe

-

7.3 Asia-Pacific

-

7.4 Latin America

-

7.5 Middle East & Africa

-

-

Market Size and Forecast (2020–2030)

-

8.1 Revenue Forecast by Region

-

8.2 Segment-Wise Demand Forecast

-

8.3 Market Trends by End-Use Industry

-

-

Competitive Landscape

-

9.1 Market Share Analysis

-

9.2 Key Company Profiles

-

9.2.1 Siemens AG

-

9.2.2 SEW-Eurodrive

-

9.2.3 Bonfiglioli Riduttori

-

9.2.4 Nord Drivesystems

-

9.2.5 ABB Ltd

-

9.2.6 Others

-

-

9.3 Product Innovation, Mergers, and Strategic Alliances

-

-

Regulatory and Efficiency Standards

-

10.1 ISO, IEC, and NEMA Standards

-

10.2 Energy Efficiency Mandates (IE2, IE3 Compliance)

-

10.3 Safety Certifications and Industrial Guidelines

-

-

Innovation and Future Outlook

-

11.1 AI Integration and Smart Drive Technologies

-

11.2 Compact Gearbox Design Innovations

-

11.3 Sustainable Manufacturing and Recyclable Components

-

-

Conclusion and Strategic Outlook

-

Appendices

-

13.1 Glossary

-

13.2 Research Methodology

-

13.3 References and Sources

-

To get a detailed Table of content/ Table of Figures/ Methodology Please contact our sales person at ( chris@marketinsightsresearch.com )

FAQ'S

For a single, multi and corporate client license, the report will be available in PDF format. Sample report would be given you in excel format. For more questions please contact:

Within 24 to 48 hrs.

You can contact Sales team (sales@marketinsightsresearch.com) and they will direct you on email

You can order a report by selecting payment methods, which is bank wire or online payment through any Debit/Credit card, Razor pay or PayPal.

Discounts are available.

Hard Copy